anti loose screw thread locked screws

Description

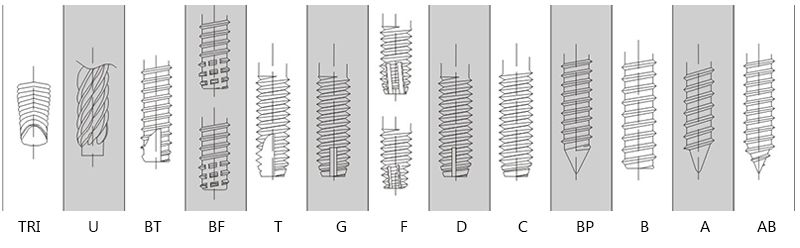

The fastener pre coating technology widely used in screw anti loosening treatment is the first successfully developed by the United States and Germany in the world. One of them is to use special technology to permanently adhere special engineering resin to the screw teeth. By utilizing the rebound properties of engineering resin materials, bolts and nuts can achieve absolute resistance to vibration and impact through compression during the locking process, completely solving the problem of screw loosening. Nailuo is a registered trademark used by Taiwan Nailuo Company on screw anti loosening treatment products, and screws that have undergone Nailuo Company's anti loosening treatment are named Nailuo Screws on the market.

There are many types of anti loosening treatments for screws on the market, one of which uses engineering resin, usually with two coating angles of 360 degrees and 180 degrees along the circumference of the screw tooth diameter.

The anti loosening treatment of screws can be divided into two main streams based on the materials used;

One method is to use special engineering plastics and special processing processes to attach the engineering plastics to the surface of the screw teeth, causing the engineering plastics to be squeezed during the locking process to generate a strong reaction force, increasing the friction between the screw teeth and providing absolute resistance to vibration, completely solving the problem of screw loosening.

Another anti loosening treatment is to pre coat special chemical adhesive onto the screws. This chemical adhesive is a high viscosity, non-toxic, and can be pre applied to threads due to contact deformation, making it suitable for automatic gluing. After drying, the adhesive will form a solid coating on the surface of the screw. This coating will undergo chemical changes as the screws lock into the nuts, which can tightly bond the screws and nuts together to prevent loosening and detachment.

The anti loosening treatment on the thread surface greatly enhances the anti loosening characteristics of the screw. Commonly used on devices or supplies that vibrate or move, such as cars and mobile precision electronic products, such as laptops, mobile phones, etc.

We can produce various types of anti loosening screws. Welcome to inquire!

Company Introduction

customer

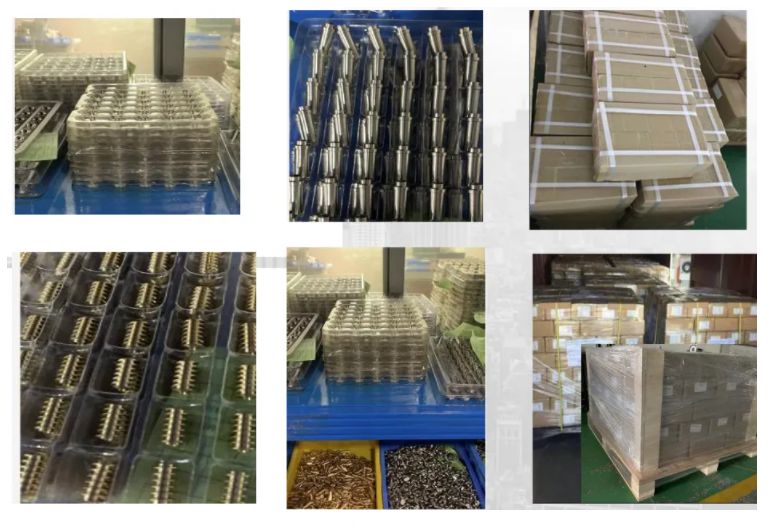

Packaging & delivery

Quality inspection

Why Choose Us

Customer

Company Introduction

Dongguan Yuhuang Electronic Technology Co., Ltd. is mainly committed to the research and development and customization of non-standard hardware components, as well as the production of various precision fasteners such as GB, ANSI, DIN, JIS, ISO, etc. It is a large and medium-sized enterprise that integrates production, research and development, sales, and service.

The company currently has over 100 employees, including 25 with more than 10 years of service experience, including senior engineers, core technical personnel, sales representatives, etc. The company has established a comprehensive ERP management system and has been awarded the title of "High tech Enterprise". It has passed ISO9001, ISO14001, and IATF16949 certifications, and all products comply with REACH and ROSH standards.

Our products are exported to more than 40 countries worldwide and are widely used in various industries such as security, consumer electronics, new energy, artificial intelligence, household appliances, automotive parts, sports equipment, healthcare, etc.

Since its establishment, the company has adhered to the quality and service policy of "quality first, customer satisfaction, continuous improvement, and excellence", and has received unanimous praise from customers and the industry. We are committed to serving our customers with sincerity, providing pre-sales, during sales, and after-sales services, providing technical support, product services, and supporting products for fasteners. We strive to provide more satisfactory solutions and choices to create greater value for our customers. Your satisfaction is the driving force for our development!

Certifications

Quality inspection

Packaging & delivery

Certifications