Black Countersunk Phillips Self Tapping Screw

Description

Self-Tapping Design for Easy Installation:

The Black Countersunk Phillips Self Tapping Screw features a self-tapping design that allows it to create its own threads as it is driven into the material. This eliminates the need for pre-drilling holes, making installation faster and more efficient. Self-tapping screws are perfect for materials like metal, plastic, wood, and composites, ensuring a secure and tight fit with minimal effort. By simplifying the installation process, this screw reduces labor time and costs, making it an excellent choice for industrial, automotive, and electronic product manufacturing. The convenience of the self-tapping feature makes it a reliable choice for businesses seeking to streamline their assembly processes while maintaining a high level of fastening performance.

Phillips Drive for Enhanced Torque and Control:

Equipped with a Phillips drive, this screw offers superior torque transfer, ensuring an efficient and controlled fastening process. The Phillips drive provides a deeper engagement between the tool and the screw, reducing the likelihood of cam-out or slippage during installation. This allows for more precise torque application, reducing the risk of over-tightening or damaging the fastener or the material. The Phillips drive is widely recognized and compatible with most standard tools, making it a convenient option for professionals across various industries. Whether working in tight spaces or requiring high torque for secure fastening, the Phillips drive ensures reliable and safe installation.

Countersunk Head for a Flush Finish:

The countersunk head design is another key feature of this screw. The head is designed to sit flush with the surface of the material once installed, providing a smooth and clean finish. This is particularly beneficial in applications where aesthetics or minimizing protrusions are important. The countersunk head also helps distribute the load evenly, reducing the risk of surface damage. This feature is commonly required in industries such as electronics, machinery, and automotive, where a smooth, flat surface is crucial. Additionally, the countersunk design minimizes the risk of accidental injury or snagging, ensuring a safer environment for workers and users.

Black Coating for Corrosion Resistance:

This self-tapping screw is coated with a durable black finish that provides enhanced corrosion resistance, making it suitable for use in environments exposed to moisture, chemicals, or varying weather conditions. The black coating not only enhances the screw's durability but also adds an aesthetic touch, making it ideal for products that require both functionality and visual appeal. The corrosion-resistant properties of the black coating ensure that the screw maintains its strength and appearance over time, even in harsh conditions, reducing the need for frequent replacements and improving the overall longevity of your assemblies.

|

Material |

Alloy/Bronze/Iron/ Carbon steel/ Stainless steel/ Etc |

|

specification |

M0.8-M16 or 0#-7/8 (inch) and we also produce according to customer's requirement |

|

Standard |

ISO,DIN,JIS,ANSI/ASME,BS/Custom |

|

Lead time |

10-15 working days as usual,It will based on the detailed order quantity |

|

Certificate |

ISO14001/ISO9001/IATf16949 |

|

Sample |

Available |

|

Surface Treatment |

We can provide customized services according to your needs |

Company introduction

With more than 30 years of experience in the hardware industry, Dongguan Yuhuang Electronic Technology Co., Ltd. specializes in the design and production of custom non-standard fasteners for large-scale B2B manufacturers in industries such as electronics, machinery, and industrial equipment. Our unwavering commitment to quality and customer satisfaction has established us as a trusted partner for premium clients across North America, Europe, and other regions. We pride ourselves on offering tailored solutions that address the unique needs of each project, ensuring exceptional performance and longevity. Driven by a philosophy of producing top-notch products and providing personalized service, we consistently aim to exceed our clients’ expectations.

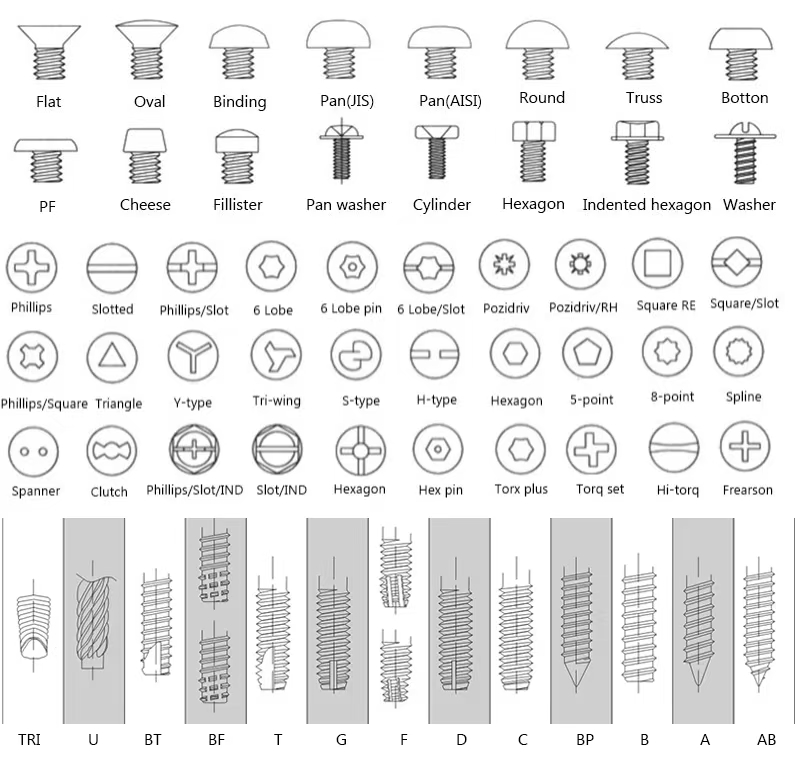

Other self tapping screw

FAQ Self Tapping Screws OEM

A self-tapping screw is a type of screw that is designed to create its own thread in a pre-drilled hole as it is driven in, eliminating the need for a separate tapping process.

Self-tapping screws usually do not require pre-drilling. The design of self-tapping screws allows them to tap themselves while being screwed into an object, using their own threads to tap, drill, and other forces on the object to achieve the effect of fixing and locking.

Self-tapping screws create their own threads in a pre-drilled hole, while normal screws require pre-drilled and pre-tapped holes for a secure fit.

Self-tapping screws may have disadvantages such as material limitations, potential for stripping, the need for precise pre-drilling, and higher costs compared to standard screws.

Avoid using self-drilling screws in hard or brittle materials where the risk of cracking or material damage is high, or when precise thread engagement is required.

Yes, self-tapping screws are suitable for wood, especially for softwoods and some hardwoods, as they can create their own threads without pre-drilling.

Self-tapping screws do not always need washers, but they can be used to distribute load, reduce stress on the material, and prevent loosening in some applications.

No, self-tapping screws are not designed to be used with nuts, as they create their own threads in the material and do not have a continuous thread along their entire length like a bolt would.

-300x300.jpg)