Black nickel sealing phillips pan head o ring screw

Description

Screw is the most common fastener in life, which is used in all aspects of life. Although the screws look simple, they contain many kinds of materials, heads, grooves, threads and prices. Therefore, as a manufacturer of non-standard special-shaped screws, when customers need to customize non-standard special-shaped screws, they must check the information provided by customers and the customization needs of non-standard special-shaped screws before starting production, so as to avoid considerable losses. The non-standard screw can be customized according to the requirements of the company and the requirements of the goods, saving the company's product development and design time and improving work efficiency.

Sealing screw specification

|

Material |

Alloy/Bronze/Iron/ Carbon steel/ Stainless steel/ Etc |

|

specification |

M0.8-M16 or 0#-7/8 (inch) and we also produce according to customer's requirement |

|

Standard |

ISO,DIN,JIS,ANSI/ASME,BS/Custom |

|

Lead time |

10-15 working days as usual,It will based on the detailed order quantity |

|

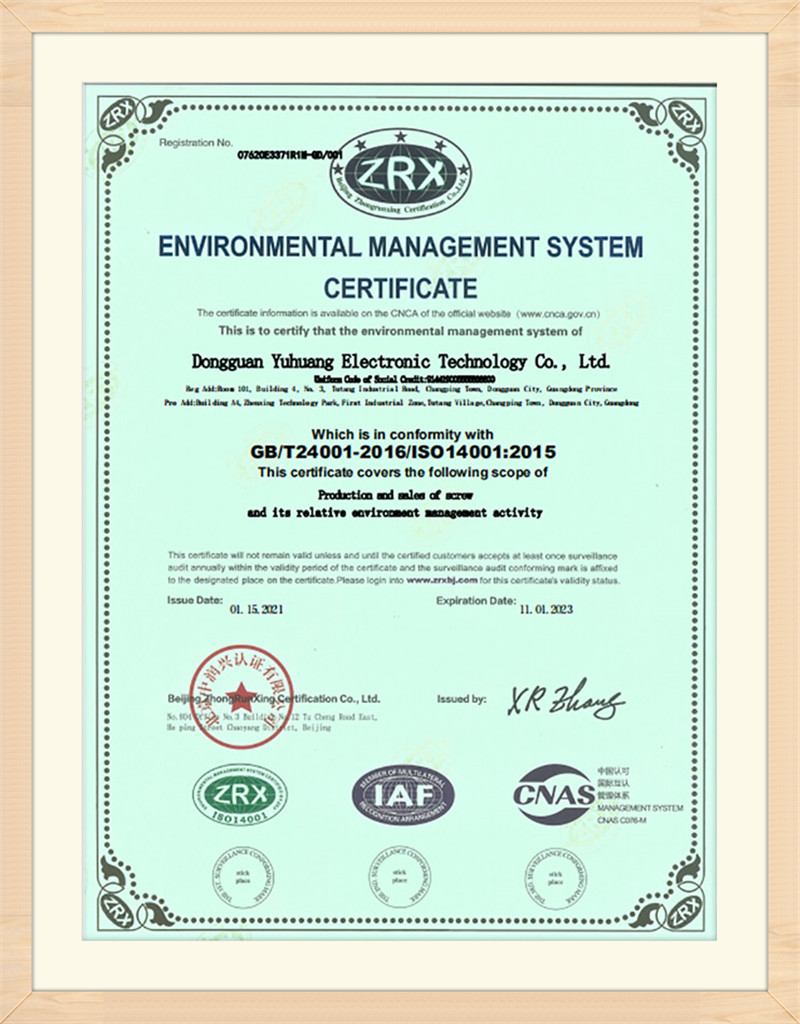

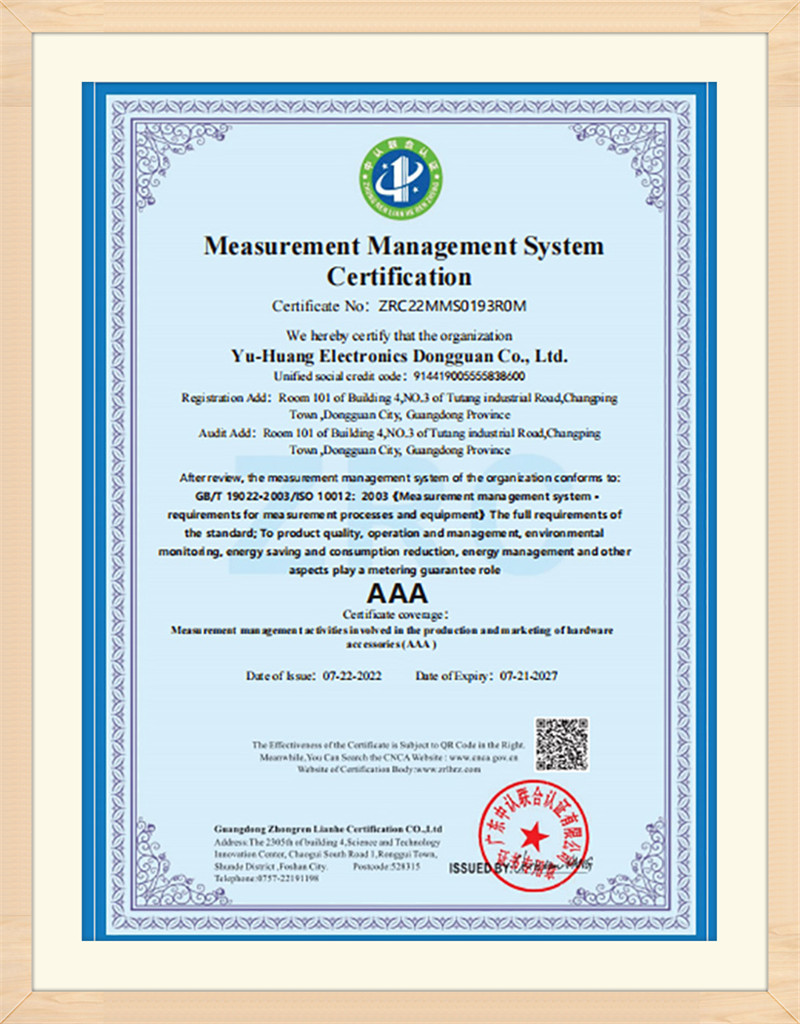

Certificate |

ISO14001/ISO9001/IATf16949 |

|

O-ring |

We can provide customized services according to your needs |

|

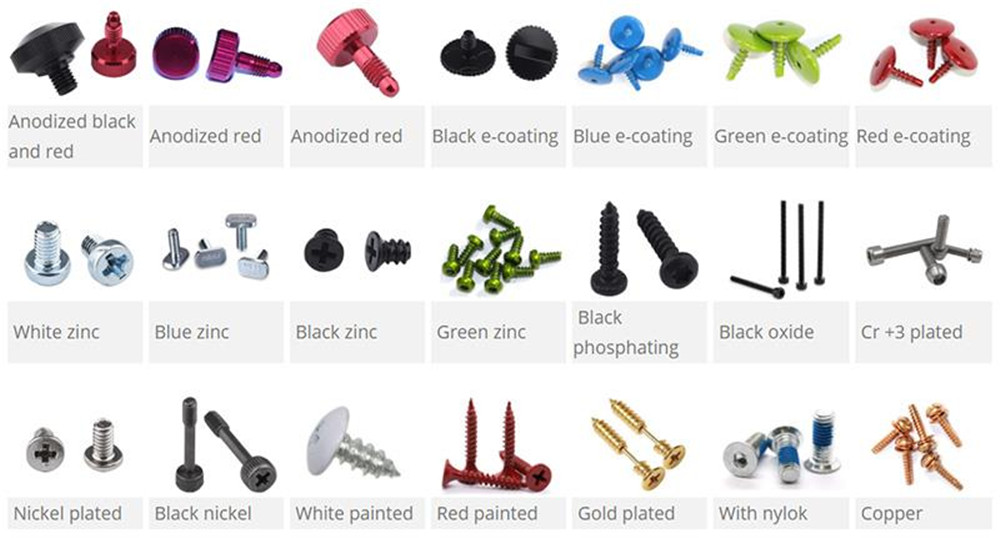

Surface Treatment |

We can provide customized services according to your needs |

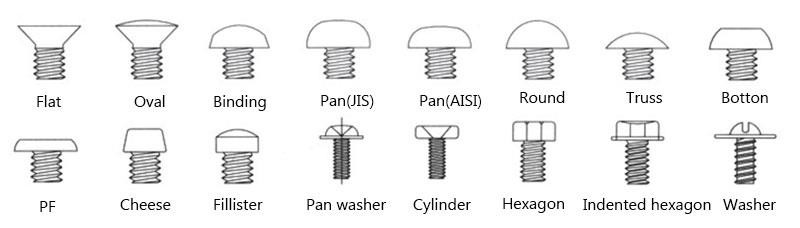

Head type of sealing screw

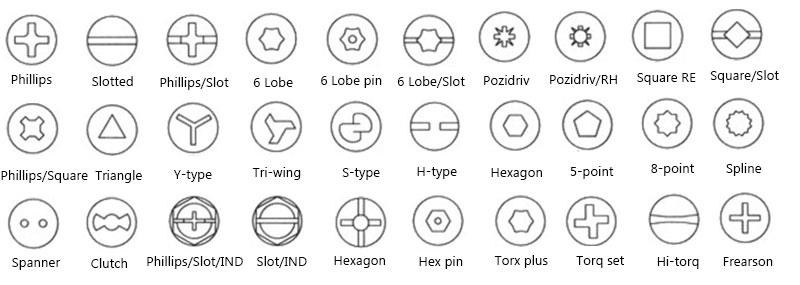

Groove type of sealing screw

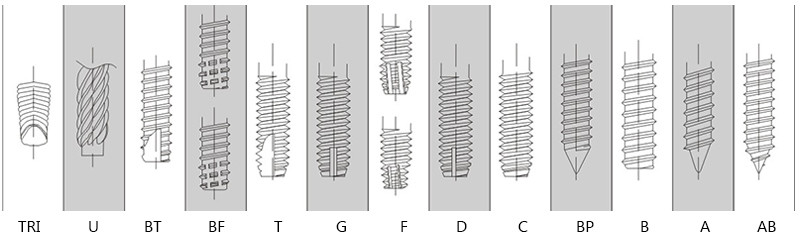

Thread type of sealing screw

Surface treatment of sealing screws

Quality Inspection

I believe that we are no strangers to screw fasteners, and we can also use them in our daily life. The screw is small, but its role is not small, so its quality cannot be ignored when buying screws. Next, the screw manufacturer will talk to you about how to find good quality screws?

First of all, look at the appearance of the screws. Good screws have high glossiness after surface processing, and the joints are not as smooth as those with sand holes. Poor screws have rough processing, many burrs, difficult landing angles, shallow thread grooves, and uneven threads. Such poor screws are easy to slip or even crack when added to furniture. Basically, they can't be reused once.

Measure the outer diameter of the screw. The outer diameter of the inferior screw will be different from the actual size. The size is not fine enough, so it may not be easy to buy it back.

According to the production scale of the screw manufacturer, many people usually go to the hardware store to buy screws, but some screws are difficult to buy in the hardware store, so we need to find the manufacturer to customize them. We need to find a screw manufacturer with large scale and sufficient production experience. The quality of the customized screws need not be worried.

We are a screw manufacturer with 30 years of production experience, mainly engaged in a series of non-standard screw customization, widely used in various industries. If you have screw procurement needs, you can contact us!

| Process Name | Checking Items | Detection frequency | Inspection Tools/Equipments |

| IQC | Check raw material: Dimension, Ingredient, RoHS | Caliper, Micrometer, XRF spectrometer | |

| Heading | Outward appearance, Dimension | First parts inspection: 5pcs each time

Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours |

Caliper, Micrometer, Projector, Visual |

| Threading | Outward appearance, Dimension, Thread | First parts inspection: 5pcs each time

Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours |

Caliper, Micrometer, Projector, Visual, Ring gauge |

| Heat treatment | Hardness, Torque | 10pcs each time | Hardness Tester |

| Plating | Outward appearance, Dimension, Function | MIL-STD-105E Normal and strict single sampling plan | Caliper, Micrometer, Projector, Ring gauge |

| Full Inspection | Outward appearance, Dimension, Function | Roller machine, CCD, Manual | |

| Packing&Shipment | Packing, Labels, Quantity, Reports | MIL-STD-105E Normal and strict single sampling plan | Caliper, Micrometer, Projector, Visual, Ring gauge |

Our certificate

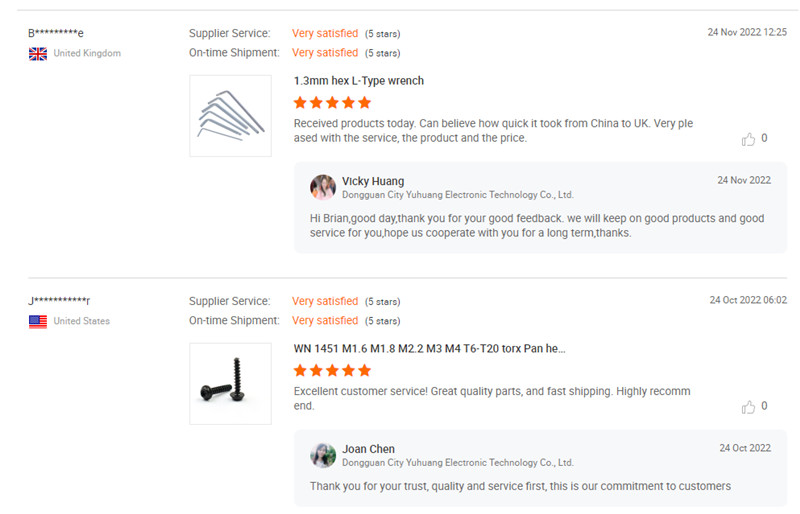

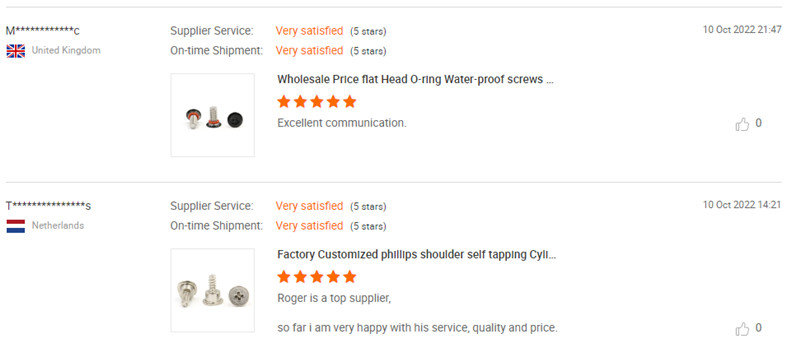

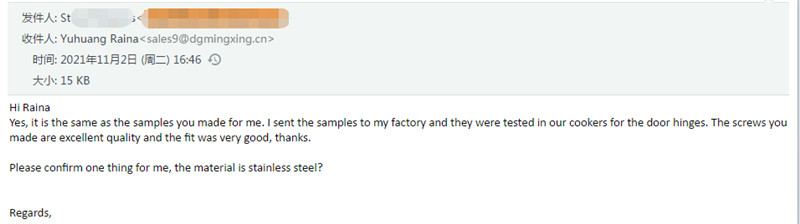

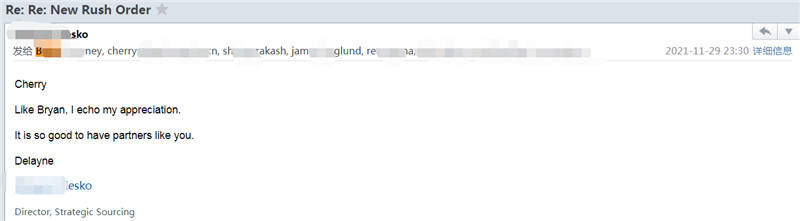

Customer Reviews

Product Application

Yuhuang professional non-standard screw manufacturer: It uses imported non-standard screw machine production equipment, precision testing instruments, and produces various standard screws such as GB, ANSI, DIN. It provides reliable quality and reasonable price according to customer requirements to support the customization of various non-standard screws. The products are mainly used in the automotive industry, household appliances, security camera systems, sports equipment, medical and other fields.