countersunk flat head slotted machine screws

Description

Stainless steel countersunk flat head slotted flat head machine screws are a commonly used fastener for connecting two or more components. As a professional screw manufacturer, Yuhuang can provide customized production services for stainless steel countersunk flat head slotted flat head machine teeth screws to meet the special needs of customers.

1、 Product Features

1. Corrosion resistance: Stainless steel countersunk flat head slotted slotted machine screws are made of stainless steel material, which has good corrosion resistance and can be used in damp or corrosive environments.

2. High strength: Stainless steel countersunk flat head slotted slotted machine teeth screws have undergone heat treatment and surface treatment, which have high strength and hardness and can withstand large loads.

3. Long service life: Stainless steel countersunk flat head slotted slotted slotted machine screws are made of high-strength alloy steel, which has undergone heat treatment and surface treatment, and has high durability and corrosion resistance.

2、 Customized services

Our factory can customize production according to customer requirements, including materials, specifications, accuracy levels, surface treatment, and other aspects. Customers can choose different materials according to their own needs, such as stainless steel, carbon steel, copper, etc; Choose different specifications, such as diameter, length, number of teeth, etc; Choose different accuracy levels; Choose different surface treatment methods, such as galvanizing, spraying, polishing, etc. Our engineering team can provide professional advice and technical support based on customer needs to ensure that products meet customer requirements.

|

Material |

Steel/Alloy/Bronze/Iron/ Carbon steel/etc |

|

Grade |

4.8/ 6.8 /8.8 /10.9 /12.9 |

|

specification |

M0.8-M12 or 0#-1/2" and we also produce according to customer's requirement |

|

Standard |

ISO,,DIN,JIS,ANSI/ASME,BS/Custom |

|

Lead time |

10-15 working days as usual,It will based on the detailed order quantity |

|

Certificate |

ISO14001/ISO9001/ IATF16949 |

|

Color |

We can provide customized services according to your needs |

|

Surface Treatment |

We can provide customized services according to your needs |

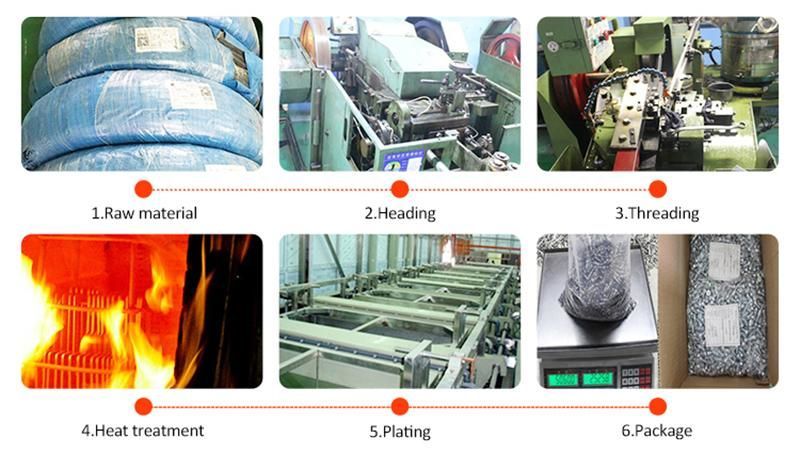

3、 Production process

Our production process is very strict, from raw material procurement to finished products leaving the factory, we go through multiple quality tests and controls. Firstly, we will inspect and screen the raw materials to ensure that they meet the standard requirements. Then, we will carry out processing techniques such as cold heading, turning, and slotting to produce high-precision stainless steel countersunk flat head slotted flat head machine screws. Finally, we will carry out surface treatment, cleaning, packaging and other processes on the finished product to ensure its quality and appearance.

4、 Service guarantee

Our factory provides comprehensive service guarantee, including pre-sales consultation, sales tracking, after-sales service, etc. In the pre-sales stage, our sales team will communicate and communicate with customers, understand their needs and requirements, and provide professional advice and technical support. During the sales phase, our production team will track and manage orders to ensure timely delivery and provide timely feedback on production progress to customers. During the after-sales stage, our customer service team will handle and resolve customer feedback and complaints to ensure customer satisfaction.

5、 Application field

Stainless steel countersunk flat head slotted machine tooth screws are widely used in various mechanical equipment and engineering fields, such as automobiles, ships, aircraft, construction, electronic equipment, and so on. They can be used to connect engines, transmissions, braking systems, circuit boards, mechanical components, etc., and play an important role.

In short, stainless steel countersunk flat head slotted slotted machine tooth screws are a commonly used fastener, and our factory can provide customized production services to meet the special needs of customers. Our production process is strict and our service guarantee is perfect, providing customers with high-quality products and services. We will continue to work hard to continuously improve product quality and service level, and create greater value for customers.

Company Introduction

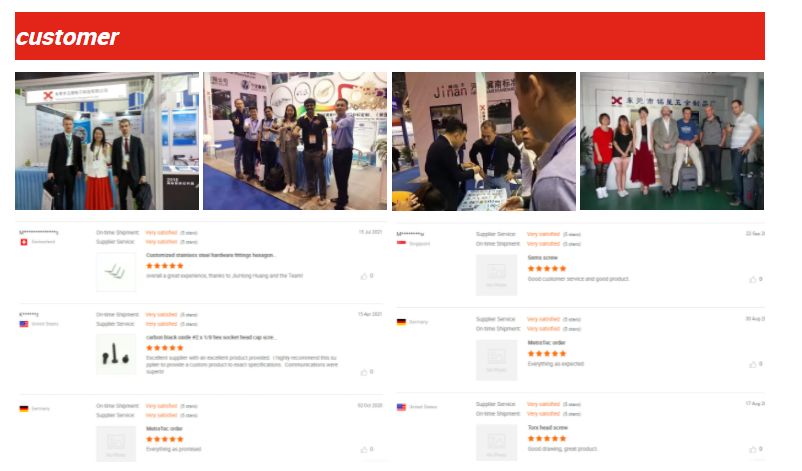

customer

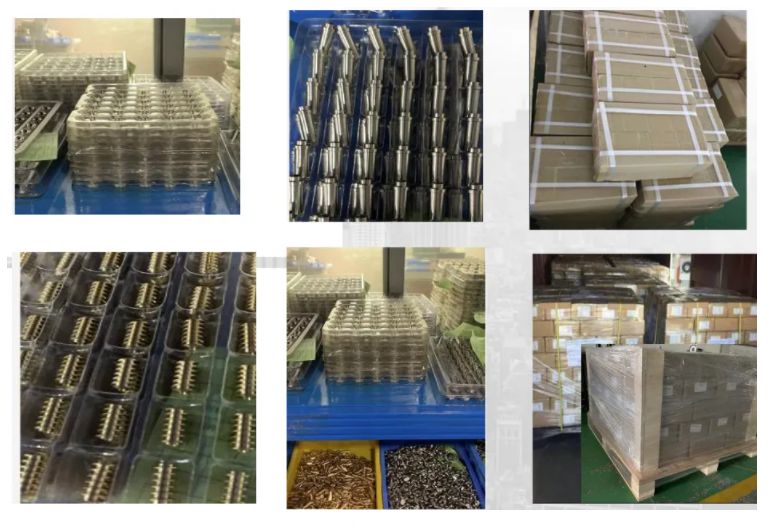

Packaging & delivery

Quality inspection

Why Choose Us

Customer

Company Introduction

Dongguan Yuhuang Electronic Technology Co., Ltd. is mainly committed to the research and development and customization of non-standard hardware components, as well as the production of various precision fasteners such as GB, ANSI, DIN, JIS, ISO, etc. It is a large and medium-sized enterprise that integrates production, research and development, sales, and service.

The company currently has over 100 employees, including 25 with more than 10 years of service experience, including senior engineers, core technical personnel, sales representatives, etc. The company has established a comprehensive ERP management system and has been awarded the title of "High tech Enterprise". It has passed ISO9001, ISO14001, and IATF16949 certifications, and all products comply with REACH and ROSH standards.

Our products are exported to more than 40 countries worldwide and are widely used in various industries such as security, consumer electronics, new energy, artificial intelligence, household appliances, automotive parts, sports equipment, healthcare, etc.

Since its establishment, the company has adhered to the quality and service policy of "quality first, customer satisfaction, continuous improvement, and excellence", and has received unanimous praise from customers and the industry. We are committed to serving our customers with sincerity, providing pre-sales, during sales, and after-sales services, providing technical support, product services, and supporting products for fasteners. We strive to provide more satisfactory solutions and choices to create greater value for our customers. Your satisfaction is the driving force for our development!

Certifications

Quality inspection

Packaging & delivery

Certifications