Custom sealing phillips washer head screw

Description

Custom sealing phillips washer head screw manufacturer.As a professional non-standard screw factory, Yuhuang focuses on the customization of various non-standard screws and has rich experience in non-standard screw customization. The reason why non-standard screws are different from standard screws is not only because of their different specifications and sizes, but also because the customized production of non-standard screws is different from that of standard screws. Non standard screws are indispensable industrial necessities in daily life, such as tiny screws used in cameras, clocks, electronics, etc. Yuhuang has been focusing on customized production and processing of non-standard screws for 30 years. There are a wide range of non-standard screws, which can be customized according to drawings and samples. The price is favorable and the quality is the same.

Sealing screw specification

|

Material |

Alloy/Bronze/Iron/ Carbon steel/ Stainless steel/ Etc |

|

specification |

M0.8-M16 or 0#-7/8 (inch) and we also produce according to customer's requirement |

|

Standard |

ISO,DIN,JIS,ANSI/ASME,BS/Custom |

|

Lead time |

10-15 working days as usual,It will based on the detailed order quantity |

|

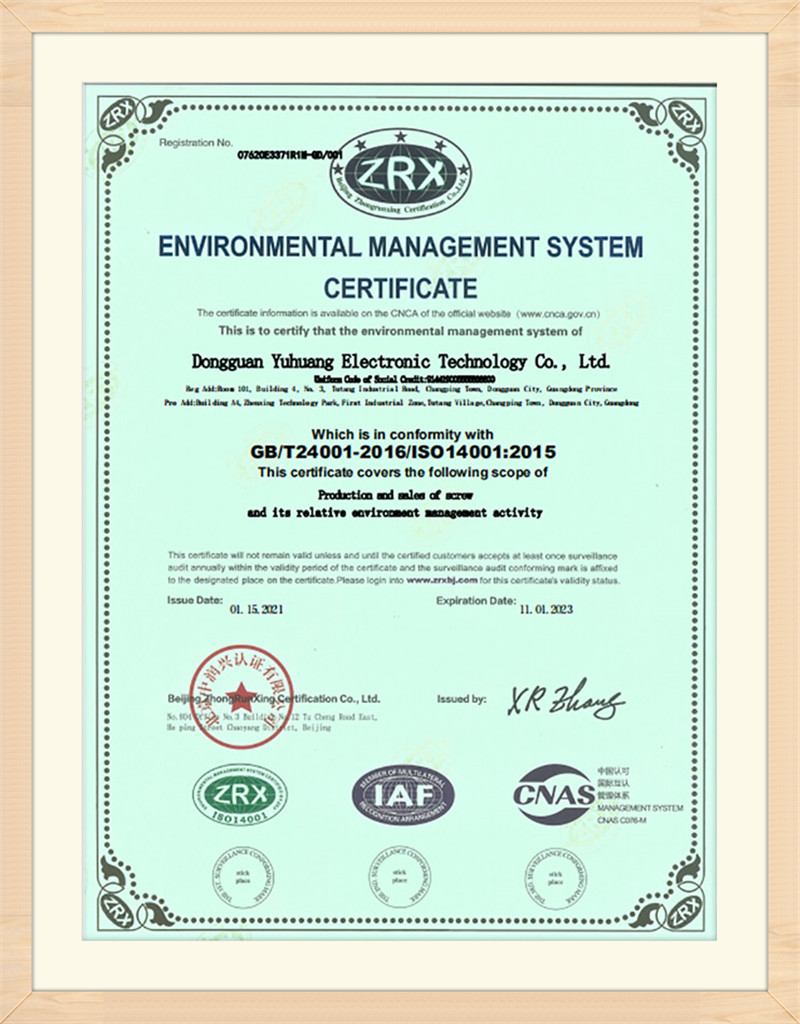

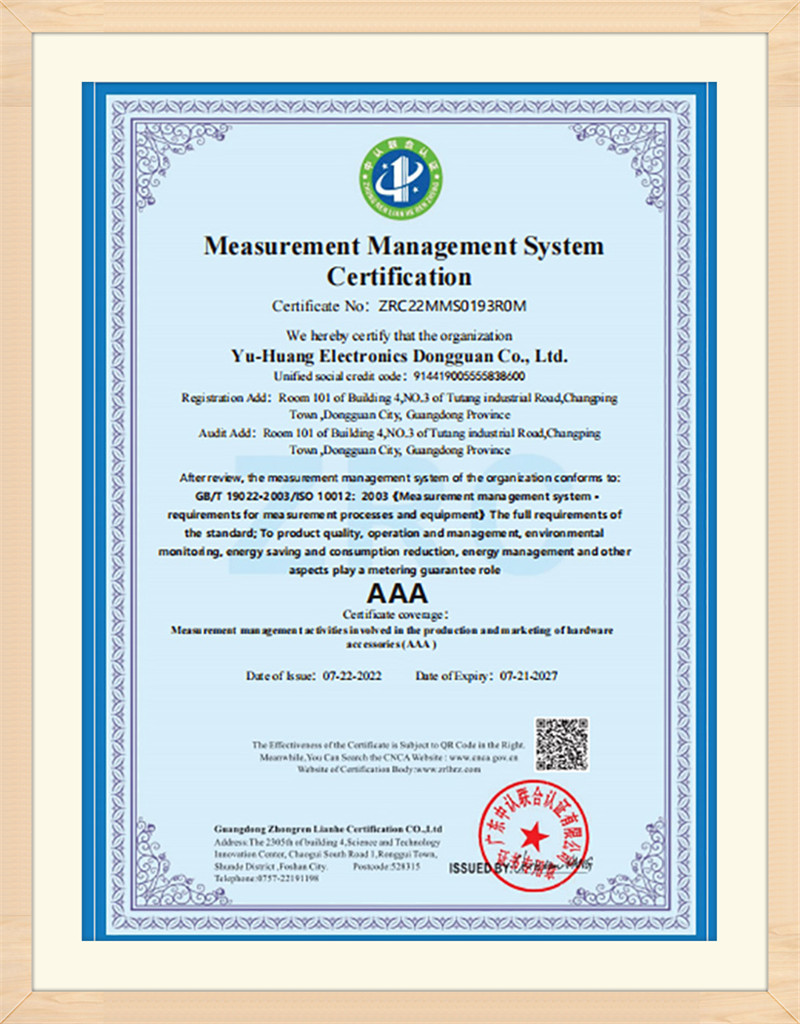

Certificate |

ISO14001/ISO9001/IATf16949 |

|

O-ring |

We can provide customized services according to your needs |

|

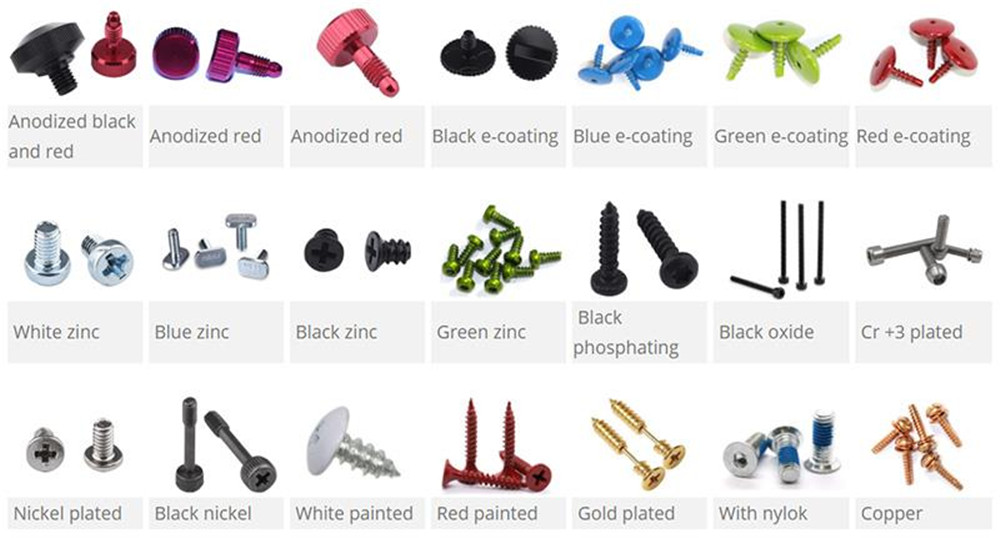

Surface Treatment |

We can provide customized services according to your needs |

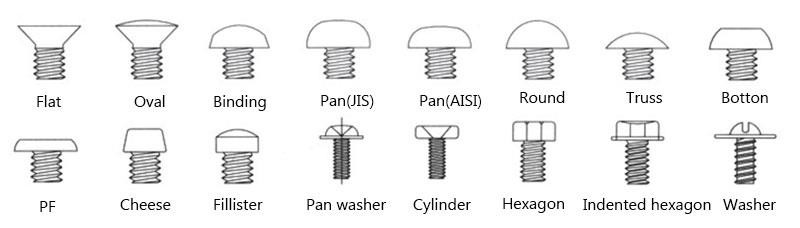

Head type of sealing screw

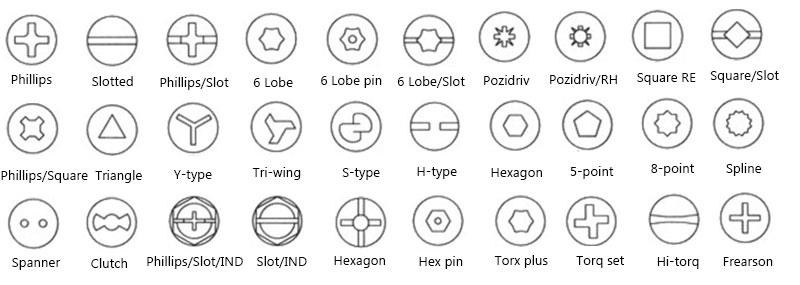

Groove type of sealing screw

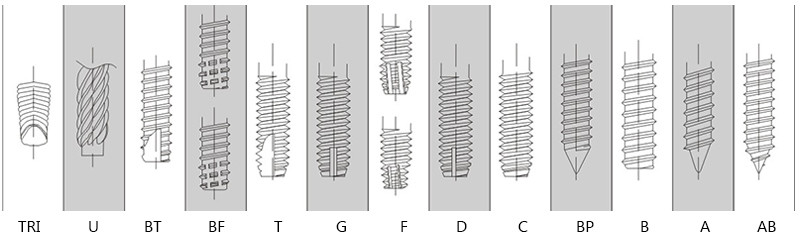

Thread type of sealing screw

Surface treatment of sealing screws

Quality Inspection

Compared with similar products, we use the best materials, all of which meet the environmental requirements, and we can provide customers with assembly suggestions and support, with after-sales service guarantee.

Before production, we will send you samples for confirmation. Only when the samples are confirmed to be correct, can we start mass production. In the production process, we comply with the ISO process control standards and conduct quality inspection from raw materials to final products to minimize the possibility of defects. If you have any questions or concerns, you can communicate with us.

I believe that in our many tests, there is almost no possibility of quality problems. If they do occur, I will describe the unqualified quality according to your description, immediately reflect the engineers and leaders of our company, and provide you with the best solution in a short time.

| Process Name | Checking Items | Detection frequency | Inspection Tools/Equipments |

| IQC | Check raw material: Dimension, Ingredient, RoHS | Caliper, Micrometer, XRF spectrometer | |

| Heading | Outward appearance, Dimension | First parts inspection: 5pcs each time

Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours |

Caliper, Micrometer, Projector, Visual |

| Threading | Outward appearance, Dimension, Thread | First parts inspection: 5pcs each time

Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours |

Caliper, Micrometer, Projector, Visual, Ring gauge |

| Heat treatment | Hardness, Torque | 10pcs each time | Hardness Tester |

| Plating | Outward appearance, Dimension, Function | MIL-STD-105E Normal and strict single sampling plan | Caliper, Micrometer, Projector, Ring gauge |

| Full Inspection | Outward appearance, Dimension, Function | Roller machine, CCD, Manual | |

| Packing&Shipment | Packing, Labels, Quantity, Reports | MIL-STD-105E Normal and strict single sampling plan | Caliper, Micrometer, Projector, Visual, Ring gauge |

Our certificate

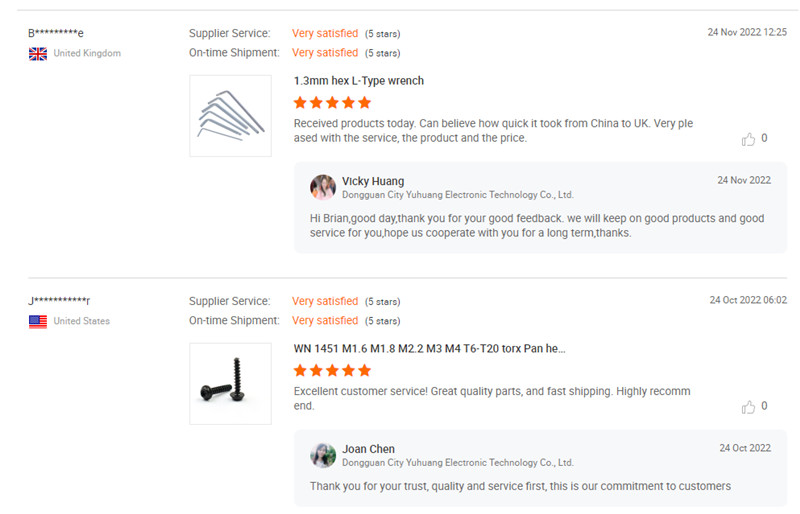

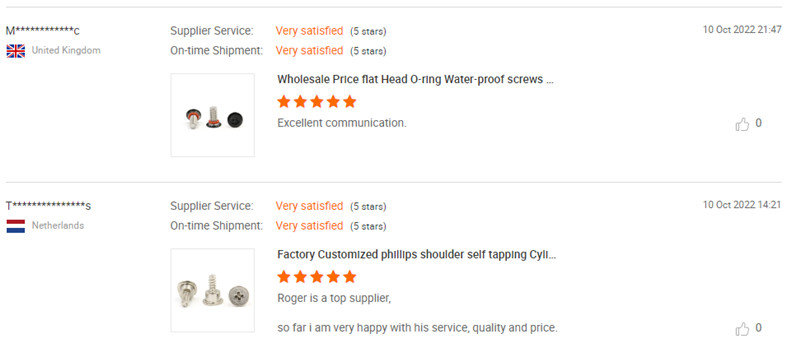

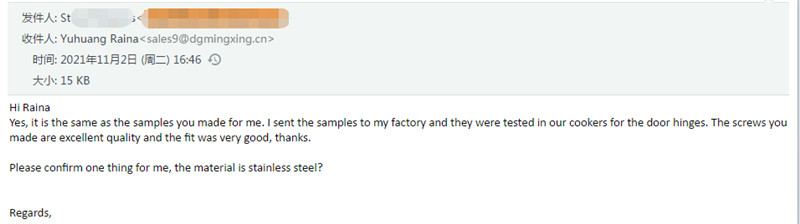

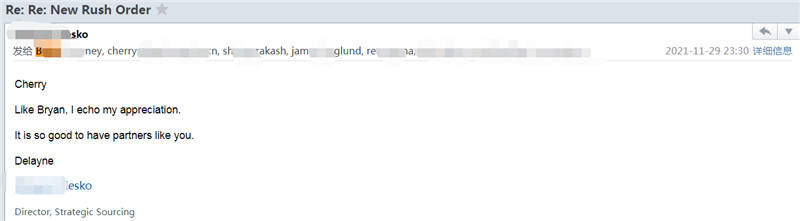

Customer Reviews

Product Application

We have more than 30 years of experience in the fastener industry. We have a professional R&D team, specializing in customized fastener design and providing solutions for suppliers. Our products are widely used in auto parts, mobile phones, computers, household appliances, new energy equipment, etc. in more than 40 countries around the world. Dongguan Yuhuang makes it easier to source any screws!