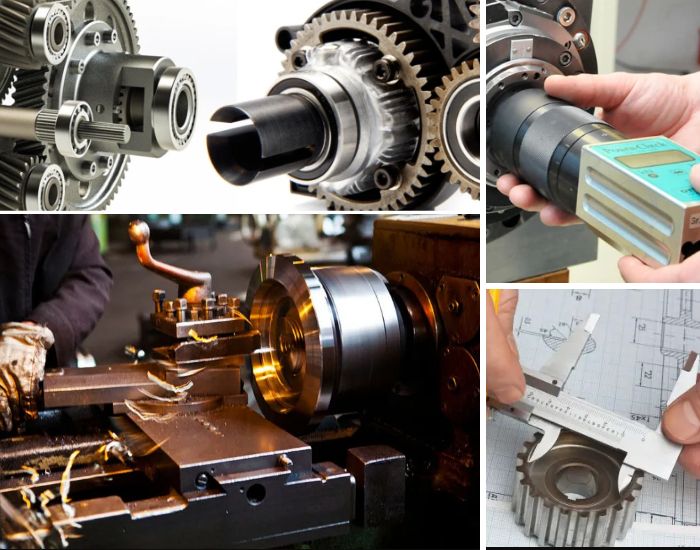

Custom Special Gears Manufacture

Gear is a common and important mechanical component, which is widely used in various mechanical equipment, including automobiles, industrial machinery, aerospace and other fields. As one of the core components of the transmission, gears achieve rotational transmission by meshing teeth with each other and transmit power from one component to another. Gears are typically made of metallic materials, such as steel, copper alloy, or aluminum alloy, to ensure their ability to carry high strength and wear resistance.

In the automotive industry, toothed Gear are widely used in transmissions, differentials, engines, and steering systems, playing an important role in speed regulation, output torque increase, and power distribution. In industrial manufacturing, gears are ubiquitous, such as in wind turbines, excavators, lifts and other equipment, which provide continuous and stable power transmission and operation support for these mechanical equipment.

In addition to large-scale industrial applications, double Helical Gear are also found in many small devices in everyday life, such as hand agitators, lawn mowers, bicycle transmissions, etc. The gears in these devices are compact and have a high power density, which allows for efficient power transfer while ensuring overall flexibility and portability.

In general, Cylindrical Gears, as a mechanical transmission element, play a vital role in the modern industry. With the continuous advancement of technology and the continuous improvement of technology, the design and manufacturing level of Customized Metal Steel Gear is also constantly improving to meet the needs of power transmission in various complex scenarios. It is foreseeable that Worm Gear will continue to play an important role in the future development of science and technology, and more innovative applications will appear.