Flat Head Phillips Cone End Self Tapping Screws

Description

Our Flat Head Phillips Cone End Self Tapping Screws are engineered for high-performance applications, combining innovative design with exceptional functionality. The flat csk head allows for a flush finish, making these screws ideal for aesthetic applications where a smooth surface is essential. The cone end design enables easy penetration into various materials, including metal, plastic, and wood, without the need for pre-drilling. This feature not only simplifies the assembly process but also enhances the overall structural integrity of the final product. With a Phillips drive, these screws provide excellent torque transfer, reducing the risk of stripping during installation.

The Flat Head Phillips Cone End Self Tapping Screw is a versatile fastening solution that excels in a variety of industrial applications. Designed specifically for electronic product manufacturers and equipment builders, these non-standard hardware fasteners are perfect for projects that require reliable and efficient fastening solutions. The cone end design allows the screw to create its own threads, ensuring a secure fit in a wide range of materials. This self-tapping capability eliminates the need for pre-drilling, saving time and labor costs during assembly.

These self tapping screws are widely utilized across various industries, including electronics, machinery, automotive, and construction. In the electronics sector, they are commonly used for assembling circuit boards, enclosures, and other components where precision and reliability are paramount. In machinery and automotive applications, these screws provide secure fastening for critical components that require high strength and durability. Their versatility makes them suitable for a wide range of applications, meeting your different needs.

Self tapping screw specification

|

Material |

Alloy/Bronze/Iron/ Carbon steel/ Stainless steel/ Etc |

|

specification |

M0.8-M16 or 0#-7/8 (inch) and we also produce according to customer's requirement |

|

Standard |

ISO,DIN,JIS,ANSI/ASME,BS/Custom |

|

Lead time |

10-15 working days as usual,It will based on the detailed order quantity |

|

Certificate |

ISO14001/ISO9001/IATf16949 |

|

Sample |

Available |

|

Surface Treatment |

We can provide customized services according to your needs |

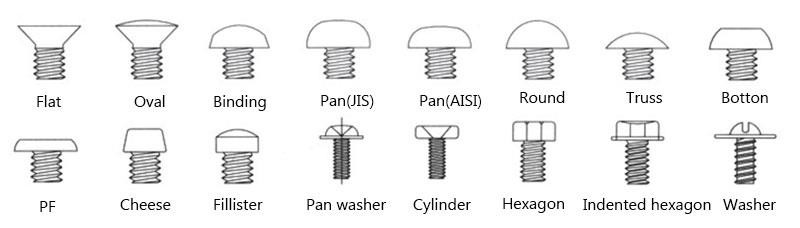

Head type of self tapping screw

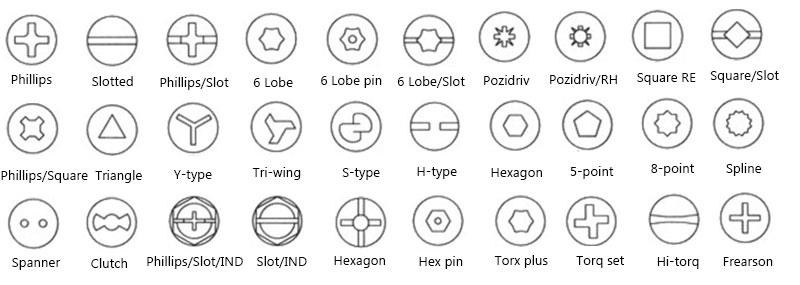

Groove type of self tapping screw

Company introduction

Dongguan Yuhuang Electronic Technology Co., Ltd., a leading high-quality fastener and hardware solution provider with over 30 years of industry experience. We specialize in manufacturing screws, washers, nuts and other important components for various industries such as electronics, machinery and automobiles. Our commitment to excellence and customer satisfaction has enabled us to establish strong partnerships with customers in more than 30 countries, including the United States, Sweden, France, the United Kingdom, Germany, Japan and South Korea.

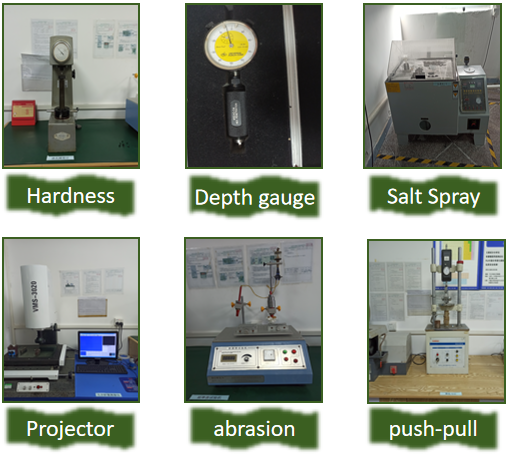

Quality Inspection

Dongguan Yuhuang Electronic Technology Co., Ltd. focuses on producing top-quality products, supported by a robust quality management system. Our advantage stems from advanced testing equipment and a comprehensive quality control process. We meticulously select raw materials, strictly inspecting each batch before production to uphold our quality standards. Throughout manufacturing, continuous monitoring and process inspections detect potential issues early, ensuring consistent and efficient production. Our skilled quality control team conducts regular audits and assessments to maintain high standards. Final inspection is crucial, with every product undergoing dimensional, performance, and visual checks before packaging and shipping. These inspections are recorded for traceability. We are dedicated to continuous improvement, regularly reviewing our quality management practices to stay ahead of industry standards and customer expectations. Investment in employee training and development further enhances our quality assurance.

Our certificate