Hex Drive Shoulder Cup Head Captive Screw

Description

Combination of Shoulder and Captive Design

The Hex Drive Shoulder Cup Head Captive Screw uniquely integrates two highly effective screw designs: the shoulder screw and the captive screw. The shoulder of the screw provides alignment and helps distribute the load evenly across the connected parts, ensuring stability during use. The captive feature prevents the screw from being lost during maintenance or disassembly, providing enhanced security and ease of handling. This combination makes the screw perfect for industrial applications where maintenance is frequent, and the risk of losing screws needs to be minimized, such as in electronic assemblies, machinery manufacturing, and automotive equipment.

Precise Alignment and Load Distribution

The shoulder of the screw acts as a step that prevents misalignment, making it easier to securely fasten components without worrying about the screw shifting. This is particularly valuable in industries requiring high precision, such as electronics and industrial machinery. The ability to distribute the load evenly also prevents stress on the surrounding components, ensuring that the fastening is durable and stable over time. The cup head design provides a smooth surface for the screw to seat securely, further improving the reliability of the connection.

Reliable and Durable Material Options

The Hex Drive Shoulder Cup Head Captive Screw is available in various materials, including alloy, bronze, iron, carbon steel, and stainless steel. These materials are chosen for their durability and ability to withstand harsh environments. For example, stainless steel is ideal for corrosion resistance in outdoor or wet conditions, while carbon steel provides excellent strength for high-load applications. The material options ensure that the screw can meet the specific needs of your application, whether it’s for electronic products, automotive components, or industrial equipment.

Customizable to Fit Your Specific Needs

With our fastener customization service, the Hex Drive Shoulder Cup Head Captive Screw can be tailored to your exact specifications. Whether you need a specific size, material, grade, or surface treatment, we can deliver a solution that fits your project perfectly. This customization capability makes it ideal for businesses with unique or specialized requirements, ensuring that the screw fits seamlessly with your assembly processes and product designs.

Meets International Quality Standards

The Hex Drive Shoulder Cup Head Captive Screw is produced to meet international standards, including ISO, DIN, JIS, ANSI/ASME, and BS. This ensures the fastener’s compatibility with global manufacturing systems and makes it suitable for applications worldwide. Additionally, we are ISO 9001 and IATF 16949 certified, guaranteeing the highest level of quality control and consistency in every screw we produce. This certification ensures that our fasteners meet the strictest quality standards, making them a trusted choice for B2B clients in North America, Europe, and beyond.

|

Material |

Alloy/Bronze/Iron/ Carbon steel/ Stainless steel/ Etc |

|

specification |

M0.8-M16 or 0#-7/8 (inch) and we also produce according to customer's requirement |

|

Standard |

ISO,DIN,JIS,ANSI/ASME,BS/Custom |

|

Lead time |

10-15 working days as usual,It will based on the detailed order quantity |

|

Certificate |

ISO14001/ISO9001/IATf16949 |

|

Sample |

Available |

|

Surface Treatment |

We can provide customized services according to your needs |

Company introduction

With over 30 years of experience, Dongguan Yuhuang Electronic Technology Co., Ltd. specialize in providing high-quality, custom fasteners for industries such as electronics, machinery, and manufacturing. Our advanced production facilities, ISO certifications, and dedicated team ensure we deliver precise, reliable solutions for large-scale clients across North America, Europe, and beyond. Trusted by global brands like Xiaomi, Huawei, and Sony, we offer tailored fasteners that streamline your production process and support your business goals.

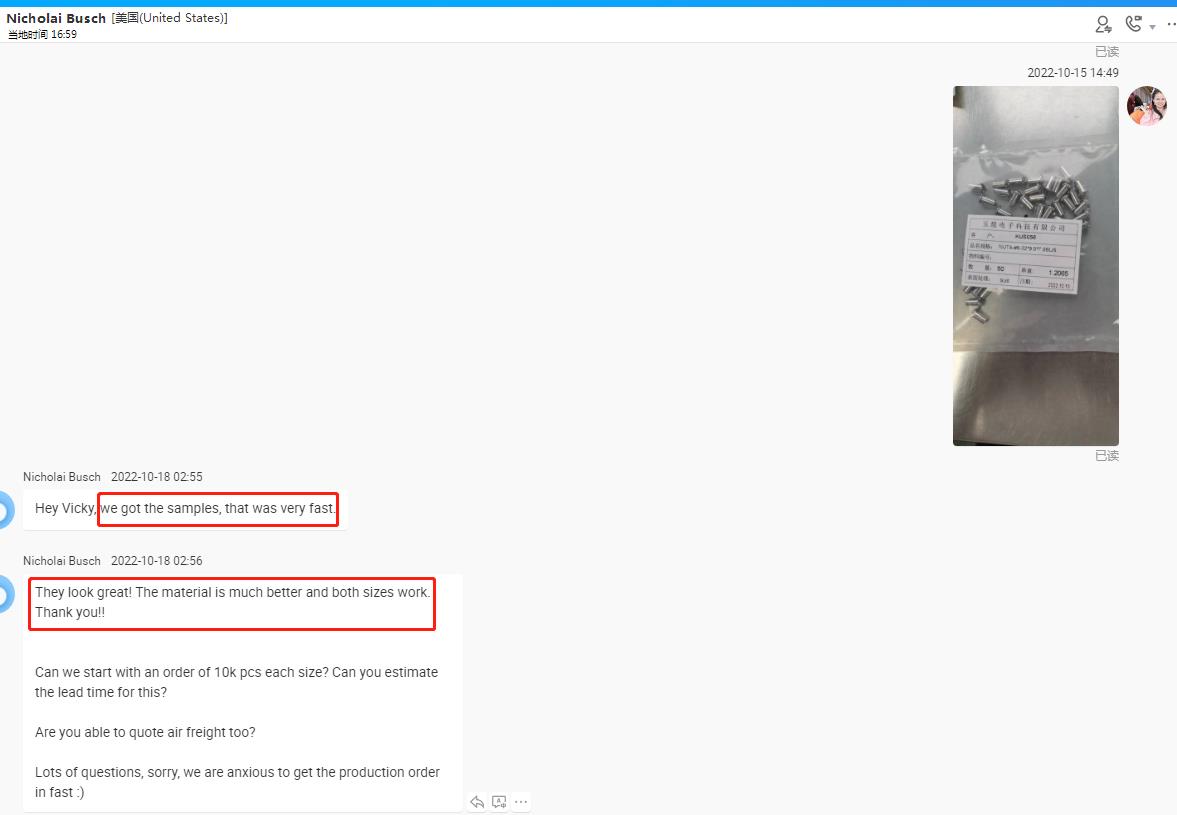

Customer Reviews

Application

Our products are widely used in industries such as electronics, automotive, and industrial machinery, where precision and durability are essential. From assembly lines to high-performance equipment, our fasteners provide reliable solutions that enhance the functionality and longevity of various applications.