Low Head Cap Screws Hex Socket Thin Head Cap Screw

Description

One of the key features of the low profile cap screw is its hex socket drive. The hex socket drive offers a secure and efficient method of installation using a hex key or Allen wrench. This drive style provides enhanced torque transfer, reducing the risk of slippage during tightening and ensuring a more reliable and consistent fastening process. The use of a hex socket drive also adds to the overall aesthetic appeal of the screw, making it suitable for visible applications where appearance matters.

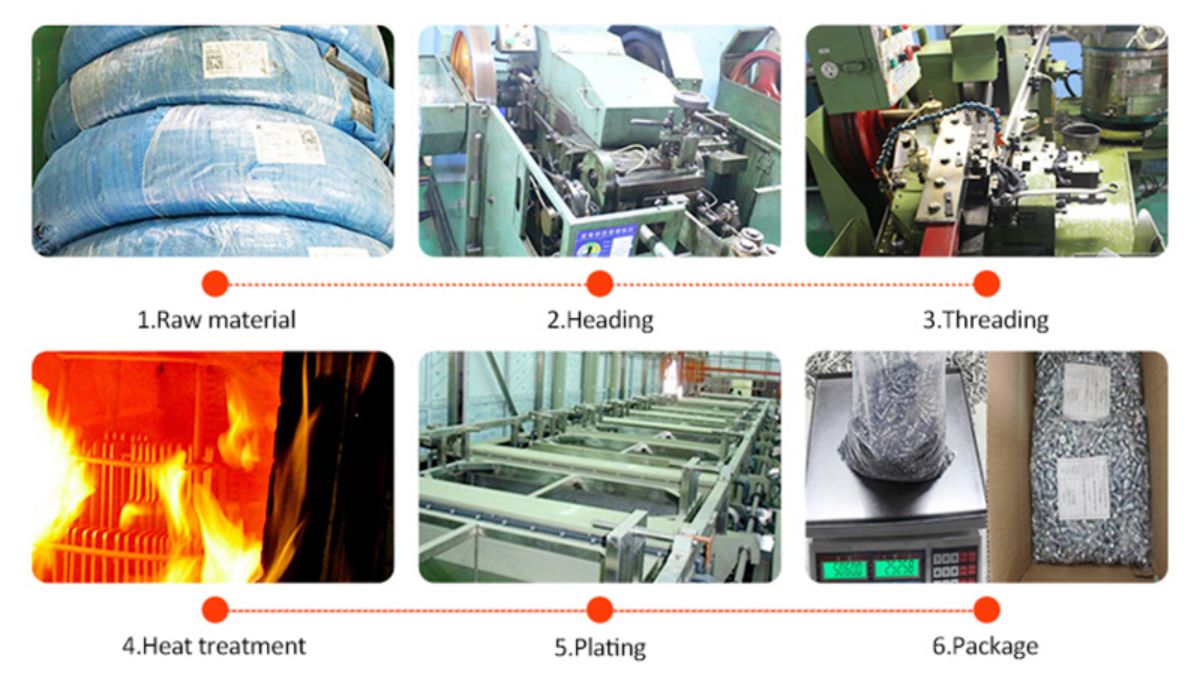

The low head profile of this screw does not compromise its strength or holding power. Each thin flat head screw is manufactured from high-quality materials, such as stainless steel or alloy steel, ensuring excellent tensile strength, corrosion resistance, and durability. These screws undergo stringent quality control measures to meet industry standards and customer expectations. The precise machining and heat treatment processes employed during production result in a screw that can withstand demanding conditions and maintain its integrity over time.

The versatility of the Thin Flat Wafer Head Screw extends beyond its design and construction. It is available in various sizes, thread pitches, and lengths, allowing for flexibility in different applications. Whether it is securing delicate electronic components, assembling intricate machinery, or fastening critical aerospace parts, this screw offers a reliable and efficient solution. Additionally, the thin head cap screw can be customized with different surface finishes, such as zinc plating or black oxide coating, to enhance its corrosion resistance and aesthetic appeal.

In summary, the Low Head Hex Socket Thin Head Cap Screw is a compact, versatile, and reliable fastener designed for applications where space is limited. With its low-profile head, hex socket drive, high-quality materials, and customization options, this screw provides a secure and efficient fastening solution in various industries. Its strength, durability, and precision make it an essential component for projects that demand both functionality and space optimization.