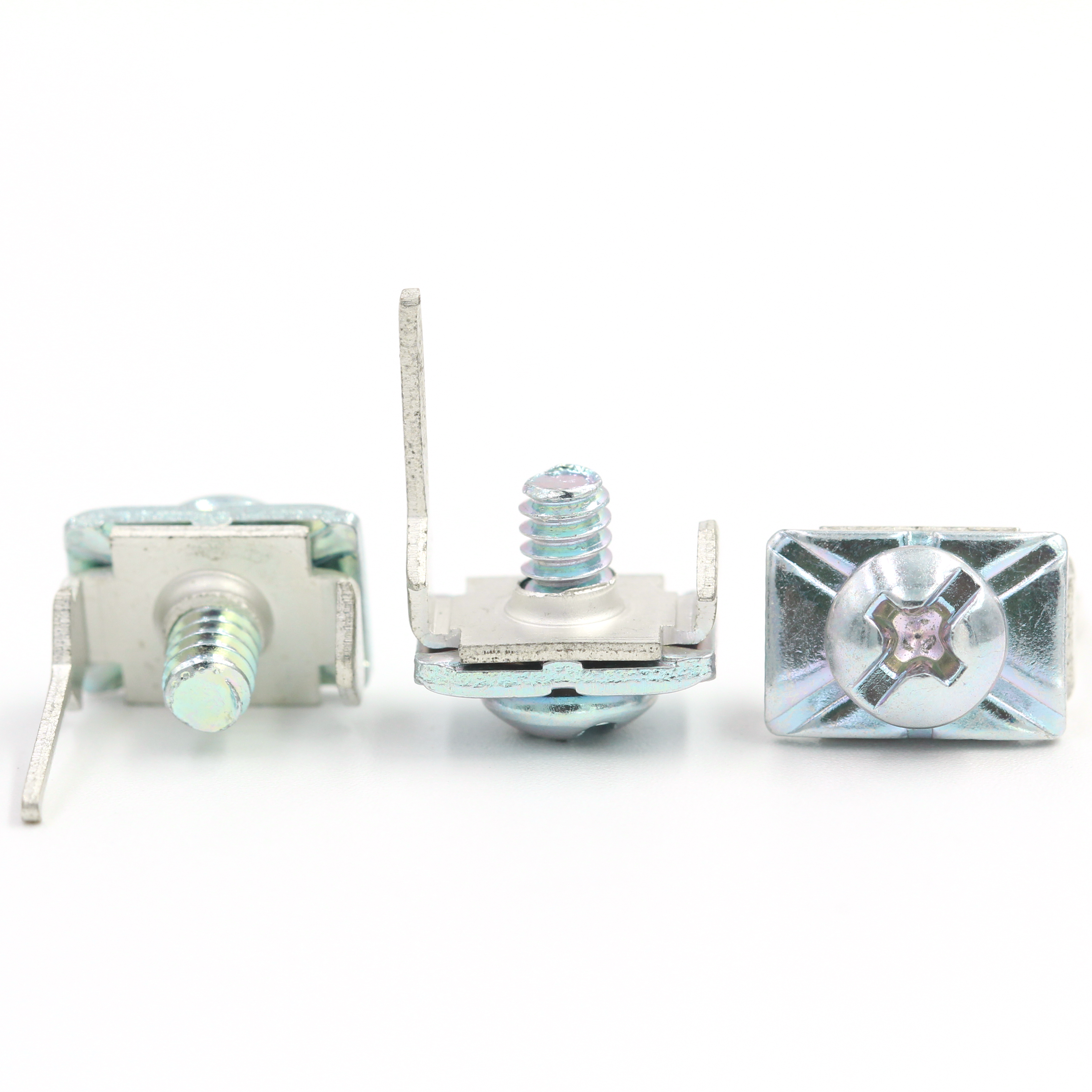

A combination screw—also called an sems screw or one-piece screw—is a fastener that merges two or more components into a single unit. This practical combination screw comes in a range of types, with different head styles and washer options, since each combination screw is built to fit specific application needs. The most common are double combination screws and three combination screws; each combination screw integrates complementary parts to deliver top-notch performance.

These combination screws outperform regular screws in assembly efficiency and anti-loosening reliability—no wonder the combination screw is a go-to for precision projects. A high-quality combination screw is used across mechanical engineering, electronics, household appliances, and furniture industries; after all, the reliability of a combination screw directly affects how durable finished products turn out. Using a combination screw cuts out the need for separate washers, slashing assembly time and avoiding the hassle of mismatched parts. That’s why so many manufacturers prioritize the combination screw for smooth, streamlined production—all thanks to the all-in-one design of the combination screw, which boosts efficiency and saves both time and effort.

Our combination screws come in materials like carbon steel, stainless steel, brass, and alloy steel, so each combination screw meets the corrosion resistance and strength demands of different environments. Every combination screw is available in multiple sizes, and we also offer custom options for specific requirements—we know a one-size-fits-all combination screw just won’t work for every industrial need. At its core, the combination screw is for fastening tasks: it makes assembly easier and saves time because the integrated components of the combination screw mean no extra hardware is required.

Popular picks in our product line include the serrated washer combination screw, sems combination screw with square washer, conical washer sems torx combination screw, and spring washer combination screw. These specialized combination screws bring extra functionality and reliability to fastening jobs, as each combination screw is engineered to tackle unique challenges—like resisting vibration or protecting surfaces.

Our combination screws are in high demand on the market, and it’s easy to see why: a well-crafted combination screw offers unbeatable versatility and efficiency, making it an essential component in modern manufacturing.

Strong Shear Resistance:

Thanks to their special structure and the use of high-strength materials, combination screws exhibit excellent shear resistance. They can withstand greater force and shear pressure, making them ideal for applications that require high-strength connections. Whether in high-pressure or violent environments, combination screws excel in providing reliable and secure fastening solutions.

Wide Range of Applications:

Combination screws find extensive applications across different industries and settings. Whether it is in construction, automotive, electronics, mechanical manufacturing, or other fields, combination screws meet various requirements and deliver outstanding connection performance. They can be utilized for securing components, assembling equipment, or protecting valuable items, among many other applications.

Error Reduction:

The installation process of combination screws is simpler and more straightforward compared to traditional screws. This reduces the likelihood of errors during assembly. Installation personnel can easily follow a few simple steps and use standard tools to complete the assembly within a few steps. This minimizes human errors and the risk of assembly failures, thereby increasing the success rate of assembly operations.

Enhanced Production Efficiency:

The convenience of assembly provided by combination screws significantly reduces the time required for assembly. This allows production lines to operate more efficiently, speeding up the overall production process. By saving time and reducing waiting periods, combination screws contribute to improved production efficiency and lower production costs.

Combination screws are versatile fasteners that provide improved assembly performance and anti-loosening features. They have a wide range of applications in various industries, and by choosing the right combination screws, you can ensure a reliable connection, reduce errors in the assembly process, and increase overall productivity.

Post time: Dec-04-2023