Precision CNC Machining Hardened Steel Shaft

Shafts are critical mechanical components, serving as the backbone of various machines and industrial equipment. As a fundamental component of mechanical power transmission systems, drive shafts play a pivotal role in enabling the transfer of rotary motion and torque between different parts of a machine or system.

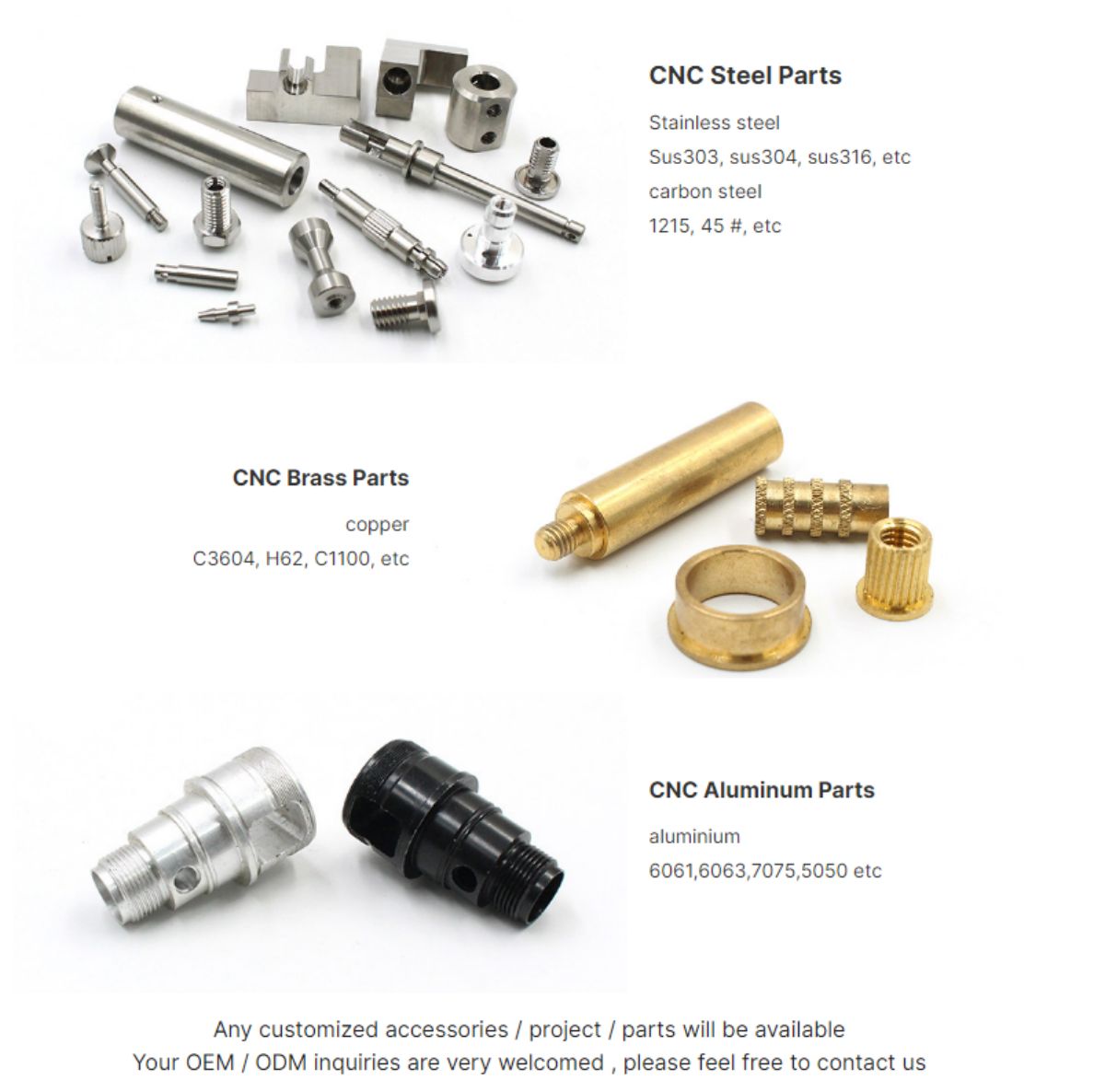

Made from high-quality materials such as steel, stainless steel, or titanium, shaft manufacturers are engineered to meet stringent performance requirements, ensuring robustness, durability, and resistance to wear and corrosion. They are meticulously crafted with precision machining techniques to guarantee accurate dimensions and surface finishes, allowing seamless integration within diverse industrial applications.

From automotive drive custom shaft and industrial machinery to power tools and agricultural equipment, Precision shaft can be customized to fit specific operational needs and environmental conditions. They exhibit versatility in design, including straight, splined, tapered, and threaded variations, catering to a wide range of mechanical configurations and power transmission requirements. Additionally, specialized coatings and treatments can carbon steel shaft be applied to enhance their resistance to harsh operating conditions, further extending their service life.

In essence, metal shaft serve as the silent workhorses behind the seamless operation of countless mechanical systems, embodying strength, reliability, and precision engineering. Their indispensable role in facilitating smooth rotational motion makes them an essential element across industries, ensuring the efficient and consistent performance of machinery and equipment.

Product Description

| Product name | OEM Custom CNC lathe turning machining precision Metal 304 Stainless Steel Shaft |

| product size | as customer's required |

| Surface treatment | polishing, electroplating |

| Packing | as per customes'requirement |

| sample | We are willing to provide with sample for quality and function testing. |

| Lead time | upon samples approved, 5-15 working days |

| certificate | ISO 9001 |

Our Advantages

Customer visits

Customer visits

FAQ

Q1. When can I get the price?

We usually offer you a quotation within 12 hours, and the special offer is not more than 24 hours. Any urgent cases, please contact us directly by phone or send email to us.

Q2:If you can not find on our website the product you need how to do?

You can send the pictures/photos and drawings of the products you need by email , we will check if we have them. We develop new models every month, Or you can send us samples by DHL/TNT, then we can develop the new model especially for you.

Q3:Can You Strictly Follow The Tolerance on The Drawing And Meet The High Precision?

Yes, we can, we can provide high precision parts and make the parts as your drawing.

Q4:How to Custom-made (OEM/ODM)

If you have a new product drawing or a sample, please send to us, and we can custom-made the hardware as your required. We will also provide our professional advices of the products to make the design to be more