precision custom screw stainless steel screw

Description

Special shaped screws can also be called special shaped bolts, which means screws without national standards are called special shaped screws. They are generally used in special occasions and purposes. The difference from ordinary screws lies in whether there are national standards.

Compared to standard screw fasteners, irregular screws exhibit superior characteristics in many aspects. In the face of huge market demand, we need to keep up with the development of the times and the pace of social development. Irregular screws are definitely the best weapon.

Advantages of customized irregular screws

1.The application of special screws can save companies a lot of installation time. For example, some electronic devices and household appliance manufacturers that use standard screw components, customized special shaped screws can greatly improve the efficiency of screwing, maximize profits, reduce labor services, and save the company's costs.

2. Customizing screws can consider the company's requirements. Can you imagine whether it is easy to change the product due to a small screw, or whether to customize this screw according to the product's requirements. I think everyone understands in their hearts that customized screws can be customized according to product requirements, saving the company's product development and design time, and improving work efficiency.

3.In addition to the function of tightening the connection, shaped screws also have the necessary aesthetic and elegant effect. Some shaped screws must be exposed (exposed) due to the design of the product. Customized shaped screws can make the appearance of the screws neat, beautiful, and unique and personalized. The special-shaped screw is a special tool for fastening the parts of utensils from the simple to the deep by using the physical and mathematical principles of the slope circular rotation and sliding friction of the block. It can also greatly add points to the product.

4.Customizing shaped screws can be applied to different natural environments, and it is very common to customize standard parts with different specifications, models, specifications, and characteristics based on different natural environments. Special shaped screws are essential industrial production products in daily life, such as small screws for applications such as digital cameras, myopia glasses, clocks, electronic devices, etc; Typical screws for televisions, electrical equipment handicrafts, traditional musical instruments, furniture, etc; For engineering projects, construction projects, and highway bridges, large and medium-sized screws and screw caps should be used; Transportation equipment, airports, electric vehicles, small cars, etc. are commonly used with size screws. Screws undertake critical daily tasks in industrial production, and if there is industrial production in the universe, the role of screws will ultimately be crucial.

Disadvantages of customizing irregular screws

1.The price of customized special shaped screws is relatively high, because the standard parts of special shaped screws are different from others, resulting in the price of customized special shaped screws being slightly higher than the usual standard parts of screws.

2. Special shaped screw components are not universal, and compared to standard screws, special shaped screws are customized and manufactured by enterprises or individuals. In other words, non-standard special shaped screw components of the same type may not be suitable for other products and manufacturing industries. The special-shaped screw is a special tool for fastening the parts of utensils from the simple to the deep by using the physical and mathematical principles of the slope circular rotation and sliding friction of the block. The standard parts are different, all manufacturing industries and all goods are available.

Company Introduction

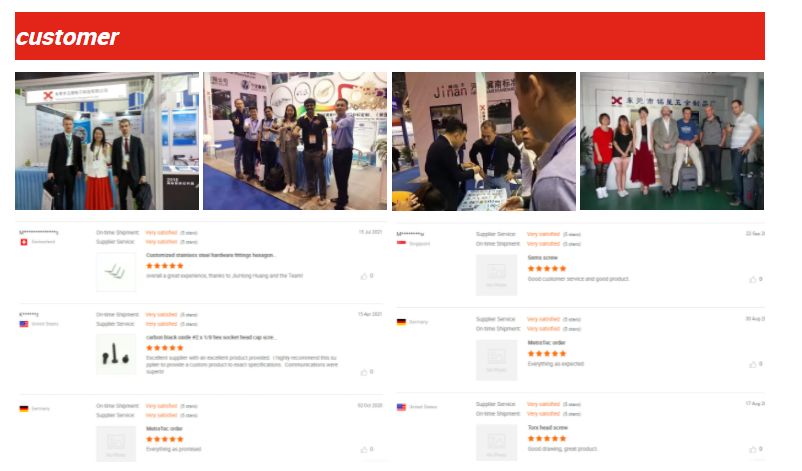

customer

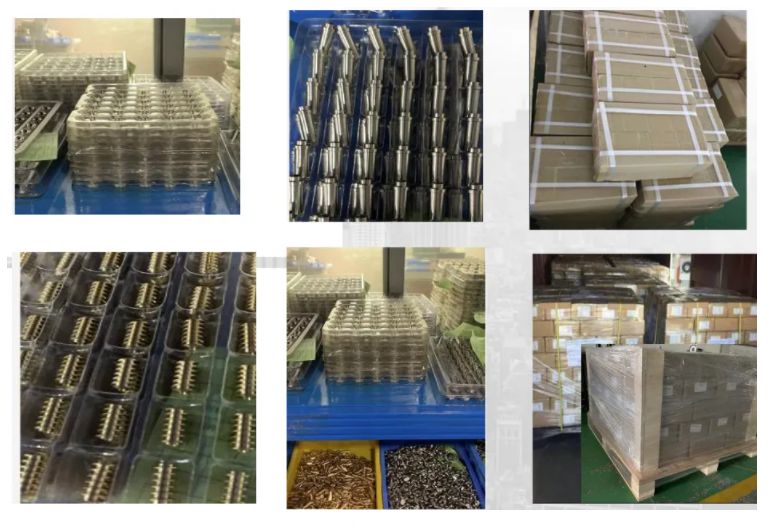

Packaging & delivery

Quality inspection

Why Choose Us

Customer

Company Introduction

Dongguan Yuhuang Electronic Technology Co., Ltd. is mainly committed to the research and development and customization of non-standard hardware components, as well as the production of various precision fasteners such as GB, ANSI, DIN, JIS, ISO, etc. It is a large and medium-sized enterprise that integrates production, research and development, sales, and service.

The company currently has over 100 employees, including 25 with more than 10 years of service experience, including senior engineers, core technical personnel, sales representatives, etc. The company has established a comprehensive ERP management system and has been awarded the title of "High tech Enterprise". It has passed ISO9001, ISO14001, and IATF16949 certifications, and all products comply with REACH and ROSH standards.

Our products are exported to more than 40 countries worldwide and are widely used in various industries such as security, consumer electronics, new energy, artificial intelligence, household appliances, automotive parts, sports equipment, healthcare, etc.

Since its establishment, the company has adhered to the quality and service policy of "quality first, customer satisfaction, continuous improvement, and excellence", and has received unanimous praise from customers and the industry. We are committed to serving our customers with sincerity, providing pre-sales, during sales, and after-sales services, providing technical support, product services, and supporting products for fasteners. We strive to provide more satisfactory solutions and choices to create greater value for our customers. Your satisfaction is the driving force for our development!

Certifications

Quality inspection

Packaging & delivery

Certifications