Screw 3/8-16×1-1/2″ thread cutting screw pan head

Description

Thread cutting screws are specialized fasteners designed to create threads in a pre-drilled or pre-tapped hole. These screws feature sharp, self-tapping threads that cut into the material as they are driven in, providing a secure and reliable connection. In this article, we will explore the features and benefits of thread cutting screws for various applications.

m1.2 thread cutting screw have a self-tapping design that allows them to create their own threads as they are driven into the material. This eliminates the need for pre-tapping or pre-drilling, saving time and effort during assembly.

The sharp threads of thread cutting screws provide excellent pull-out resistance, ensuring a strong and secure connection. This is particularly important in applications where the fastened components may experience tension or vibration.

stainless steel thread cutting screws are versatile and can be used with various materials, including metals, plastics, and wood. They are commonly used in industries such as construction, automotive, electronics, and furniture.

Thread cutting screws are available in a wide range of sizes, thread types, and head styles to accommodate different application requirements. This allows for flexibility and customization when selecting the appropriate screw for a specific project.

The cutting action of thread cutting screws creates deep and precise threads, which results in enhanced thread engagement and improved load distribution. This helps to increase the strength and stability of the fastened joint.

Thread cutting screws are often made from corrosion-resistant materials such as stainless steel or coated with protective finishes. This ensures their durability and longevity, even in harsh environments or outdoor applications.

Thread cutting screws can be easily installed using standard tools such as screwdrivers or power drills. The self-tapping design allows for quick and efficient assembly, reducing labor time and costs.

Thread cutting screws offer a cost-effective solution for fastening applications. Their ability to create threads eliminates the need for additional tapping or drilling operations, saving both time and money during assembly.

Thread cutting screws are versatile fasteners that provide a secure and reliable connection in various applications. With their self-tapping design, high pull-out resistance, suitability for different materials, wide range of sizes and types, enhanced thread engagement, corrosion resistance, easy installation, and cost-effectiveness, these screws are widely used across industries. Whether it's in construction, automotive, electronics, or furniture, thread cutting screws offer an efficient and effective solution for your fastening needs.

If you have any further questions or require additional information, please feel free to ask. Thank you for considering thread cutting screws for your applications.

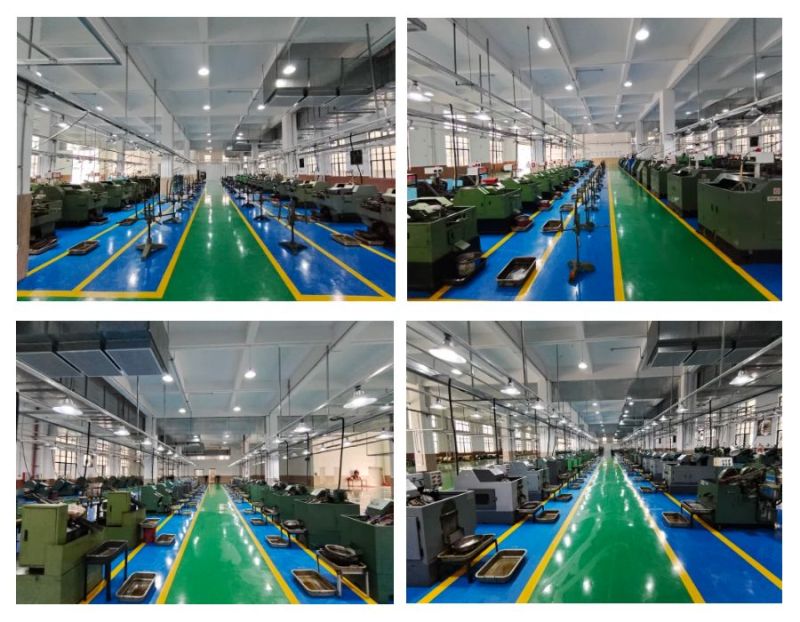

Company Introduction

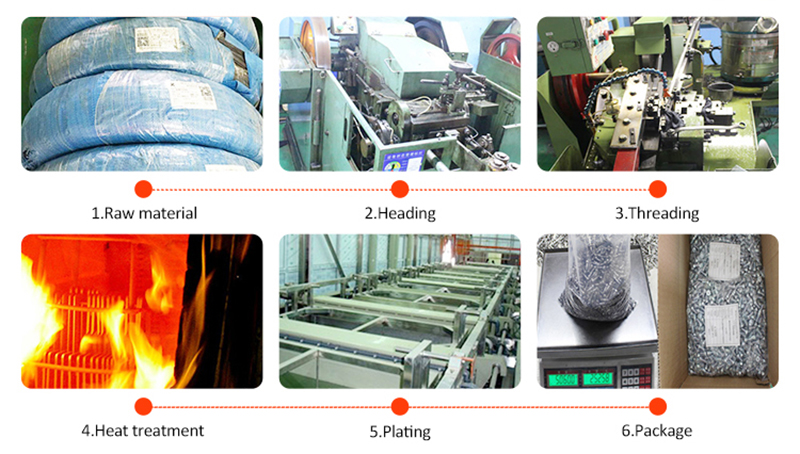

technological process

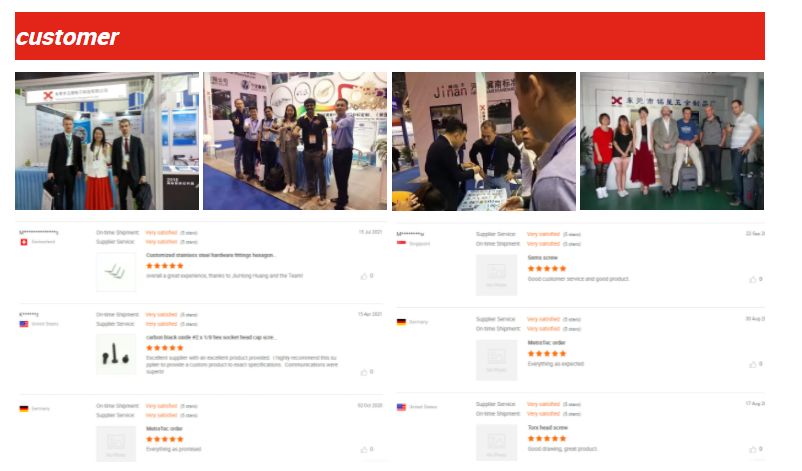

customer

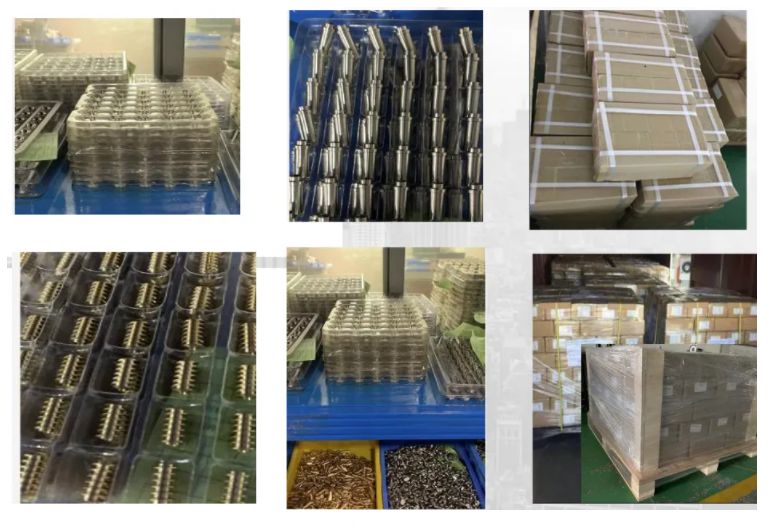

Packaging & delivery

Quality inspection

Why Choose Us

Customer

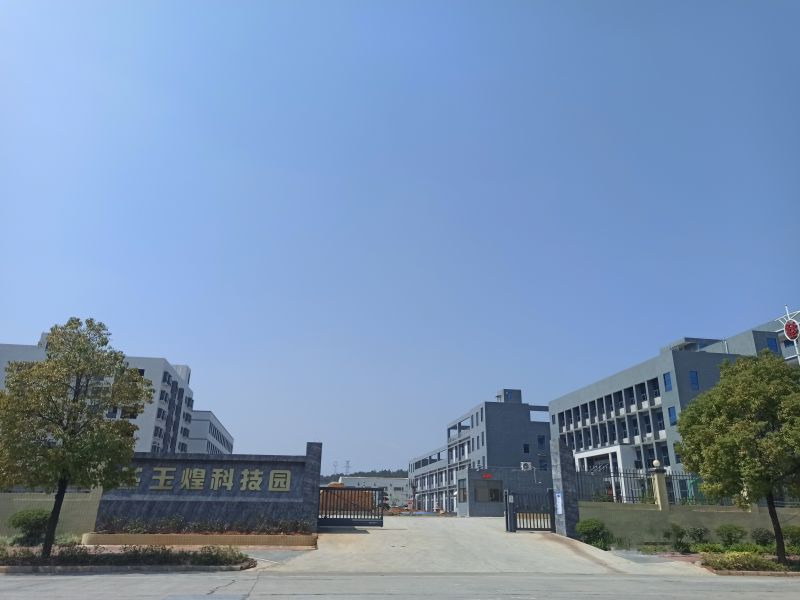

Company Introduction

Dongguan Yuhuang Electronic Technology Co., Ltd. is mainly committed to the research and development and customization of non-standard hardware components, as well as the production of various precision fasteners such as GB, ANSI, DIN, JIS, ISO, etc. It is a large and medium-sized enterprise that integrates production, research and development, sales, and service.

The company currently has over 100 employees, including 25 with more than 10 years of service experience, including senior engineers, core technical personnel, sales representatives, etc. The company has established a comprehensive ERP management system and has been awarded the title of "High tech Enterprise". It has passed ISO9001, ISO14001, and IATF16949 certifications, and all products comply with REACH and ROSH standards.

Our products are exported to more than 40 countries worldwide and are widely used in various industries such as security, consumer electronics, new energy, artificial intelligence, household appliances, automotive parts, sports equipment, healthcare, etc.

Since its establishment, the company has adhered to the quality and service policy of "quality first, customer satisfaction, continuous improvement, and excellence", and has received unanimous praise from customers and the industry. We are committed to serving our customers with sincerity, providing pre-sales, during sales, and after-sales services, providing technical support, product services, and supporting products for fasteners. We strive to provide more satisfactory solutions and choices to create greater value for our customers. Your satisfaction is the driving force for our development!

Certifications

Quality inspection

Packaging & delivery

Certifications