Screw Phillips Rounded Head Thread-Forming Screws m4

Description

Thread forming screws are specialized fasteners designed for use in plastic products. Unlike traditional thread-cutting screws, these screws create threads by displacing material rather than removing it. This unique feature makes them ideal for applications where a secure and reliable fastening solution is required in plastic components. In this article, we will explore the features and benefits of thread forming screws for plastic products.

Pt screws have a unique design that allows them to create threads as they are driven into the plastic material. The screw's thread geometry and flute design facilitate the displacement of plastic material, resulting in precise and strong threads. This ensures a secure and reliable connection between the screw and the plastic component.

The thread-forming process creates threads with excellent pull-out resistance in plastic materials. This is particularly important in applications where the plastic components may experience tension or vibration.

k30 thread forming screws can cause stress concentration and cracking in plastic materials due to the removal of material during installation. Thread forming screws, on the other hand, displace the plastic material, reducing the risk of stress concentration and cracking.

The thread-forming process distributes the load more evenly along the length of the screw, reducing the risk of localized stress points. This helps to improve the overall strength and integrity of the fastened joint.

The thread forming process creates a tight and secure connection that is less prone to loosening caused by vibrations or external forces. This ensures the long-term stability and reliability of the fastened plastic components.

plastic thread forming screws find extensive use in various industries, including automotive, electronics, consumer goods, and medical devices. They are commonly used to fasten plastic components such as housings, panels, brackets, and connectors.

Thread-Forming Screws m4 are compatible with a wide range of plastic materials, including ABS, polycarbonate, nylon, and polypropylene. This versatility makes them suitable for various plastic product applications.

High-Low Thread Forming Screws offer a cost-effective solution for fastening plastic components. The elimination of the need for tapping or pre-drilling reduces assembly time and costs associated with additional operations.

Thread forming screws are an excellent choice for fastening plastic products. With their thread-forming design, high pull-out resistance, reduced stress and cracking, enhanced load distribution, and improved resistance to loosening, these screws provide secure and reliable connections in plastic components. Their compatibility with different plastic materials and cost-effectiveness make them a preferred choice across various industries.

If you have any further questions or require additional information, please feel free to ask. Thank you for considering thread forming screws for your plastic product applications.

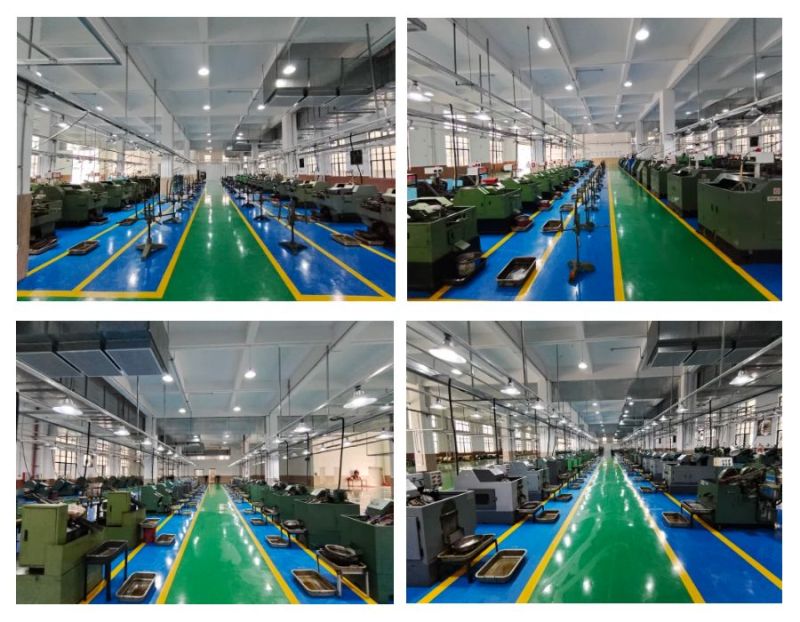

Company Introduction

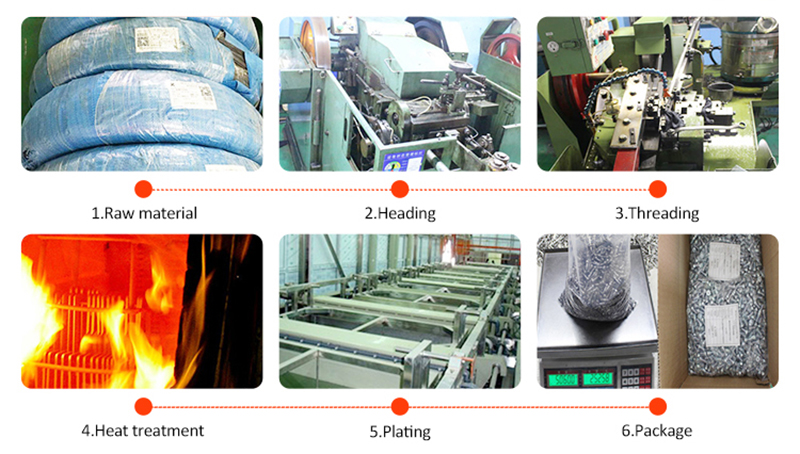

technological process

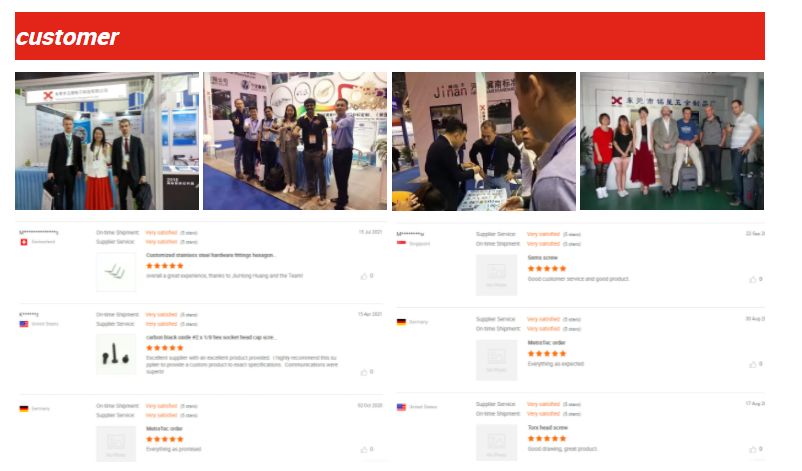

customer

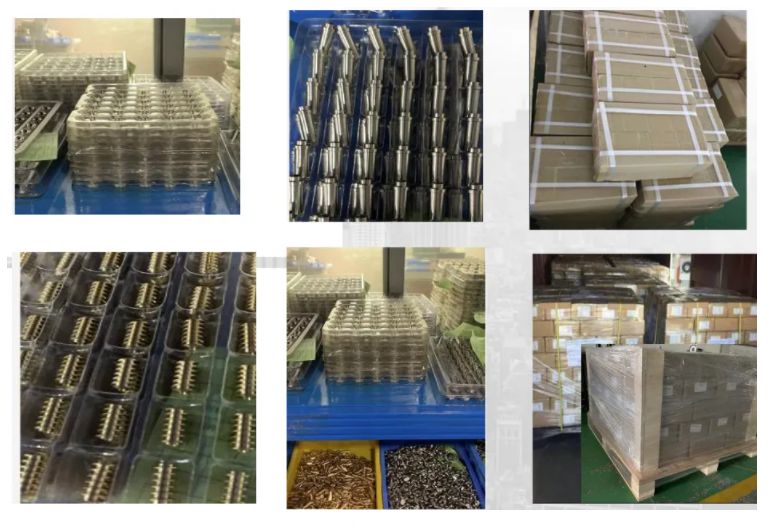

Packaging & delivery

Quality inspection

Why Choose Us

Customer

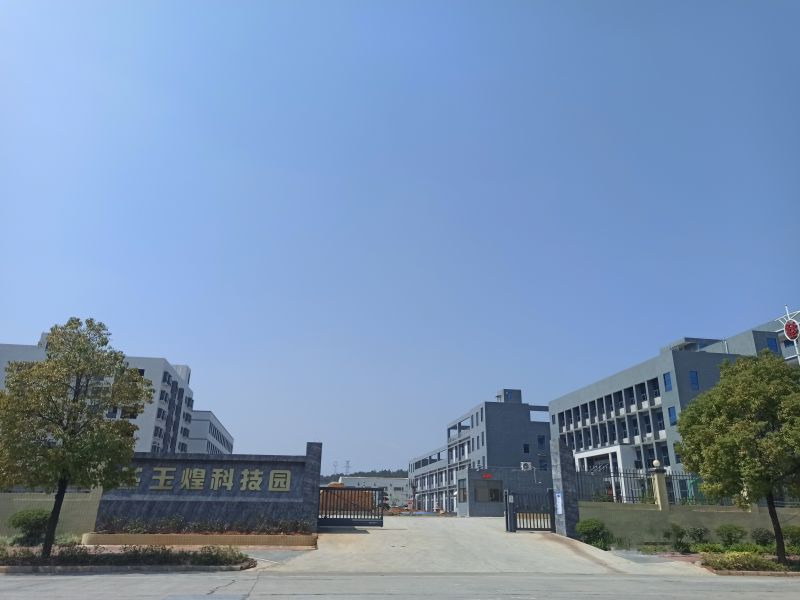

Company Introduction

Dongguan Yuhuang Electronic Technology Co., Ltd. is mainly committed to the research and development and customization of non-standard hardware components, as well as the production of various precision fasteners such as GB, ANSI, DIN, JIS, ISO, etc. It is a large and medium-sized enterprise that integrates production, research and development, sales, and service.

The company currently has over 100 employees, including 25 with more than 10 years of service experience, including senior engineers, core technical personnel, sales representatives, etc. The company has established a comprehensive ERP management system and has been awarded the title of "High tech Enterprise". It has passed ISO9001, ISO14001, and IATF16949 certifications, and all products comply with REACH and ROSH standards.

Our products are exported to more than 40 countries worldwide and are widely used in various industries such as security, consumer electronics, new energy, artificial intelligence, household appliances, automotive parts, sports equipment, healthcare, etc.

Since its establishment, the company has adhered to the quality and service policy of "quality first, customer satisfaction, continuous improvement, and excellence", and has received unanimous praise from customers and the industry. We are committed to serving our customers with sincerity, providing pre-sales, during sales, and after-sales services, providing technical support, product services, and supporting products for fasteners. We strive to provide more satisfactory solutions and choices to create greater value for our customers. Your satisfaction is the driving force for our development!

Certifications

Quality inspection

Packaging & delivery

Certifications