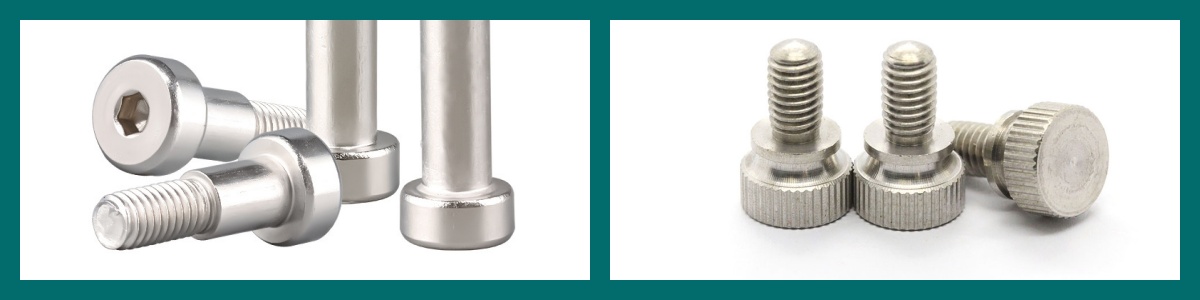

Shoulder bolts are a type of threaded fastening element characterized by a head, a non-threaded section called the shoulder, and a threaded portion that interfaces with mating parts up to the shoulder. The shoulder remains visible above the mating material once the threaded section is in place, offering a smooth, cylindrical surface for other components to revolve around, pivot on, or attach to.

Despite various design options, these bolts share three key attributes:

A head (commonly a cap head, but alternatives such as flat or hex heads exist)

A precisely dimensioned shoulder within tight tolerances

A threaded section (crafted for accuracy; generally UNC/coarse threading, though UNF threading is also an option)

Features of step screws

Shoulder screws have different designs for different application scenarios.

Head Texture

These bolts come with either a knurled head, which has vertical grooves extending across its length, or a smooth head. The knurled head minimizes the chance of over-tightening and offers enhanced grip, whereas a smooth head is preferred for a more visually appealing finish.

Head Shape

The configuration of the bolt head affects both the installation process and the final positioning against the mating surface. While cap heads are prevalent among shoulder bolts, alternative head styles such as hexagonal and flat heads are also accessible. For applications where a minimal protrusion is desired, low-profile and ultra-low-profile head options are offered.

Drive Type

The bolt's drive system specifies the type of tool necessary for installation and the stability of its bite on the head. Prevalent drive systems include assorted socket head designs, such as hex and six-point sockets. These systems promote sturdy fastening with a decreased chance of head damage or loss of grip. Furthermore, slotted drives are also widely used and are compatible with a variety of installation tools, providing flexibility in their application.

What are the characteristics of Shoulder screw threads?

Extended Threads: These possess thread lengths that surpass the standard, offering increased grip and stability.

Oversized Threads: While conventional shoulder screw threads are narrower than the shoulder width, oversized threads match the shoulder's diameter, which is advantageous when the shoulder must protrude into the mating hole for added support.

Oversized and Extended Threads: These screws feature a combination of the two aforementioned traits, providing both enhanced holding strength and shoulder extension.

Nylon Patch: Alternatively known as a self-locking patch, this component is affixed to the bolt's threads and, upon installation, triggers adhesive chemicals that firmly lock the bolt within the threaded hole.

HOT SALES:Shoulder Screw OEM

How to choose the material of Shoulder screws?

Carbon Steel Screws: Strong and cost-effective, but prone to corrosion without treatment.

Stainless Steel Screws: Durable and resistant to corrosion, but not as hardenable as carbon steel.

Alloy Steel Screws: Balanced strength and flexibility, suitable for heavy use after heat treatment.

Brass Screws: Good for electrical and thermal conductivity, but less strong and more susceptible to tarnish.

Aluminum Screws: Lightweight and resistant to corrosion, but not as strong and can gall when in contact with different metals.

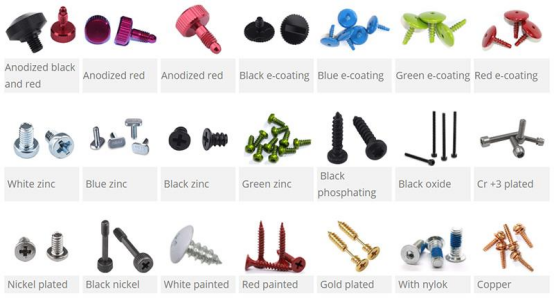

Surface treatment of Shoulder screws

Black oxide finishes do not alter the screw's dimensions and provide a treated black rust appearance, mainly used for aesthetic purposes.

Chrome coating offers a bright, reflective finish that is both decorative and highly durable, applied through electroplating.

Zinc plated coatings serve as sacrificial anodes, protecting the underlying metal, and are applied as a fine white dust.

Other coatings like galvanization and phosphating are common for specific hardware applications, such as screws used in fence or window installations.

For more information about step screws, please contact us at yhfasteners@dgmingxing.cn

FAQ

A shoulder screw is a type of screw with a reduced-diameter non-threaded shank (shoulder) that extends beyond the threaded portion, often used for pivot points or alignment in mechanical assemblies.

Shoulder screws can be expensive due to the precision required in their manufacturing and the use of high-quality materials to ensure durability and performance.

The tolerance of a shoulder screw hole typically depends on the specific application and needs, but it generally ranges within a few thousandths of an inch to ensure proper fit and function.

Screwed connections are made with threaded fasteners that are turned into pre-tapped holes, while bolted connections use bolts and nuts to assemble components.