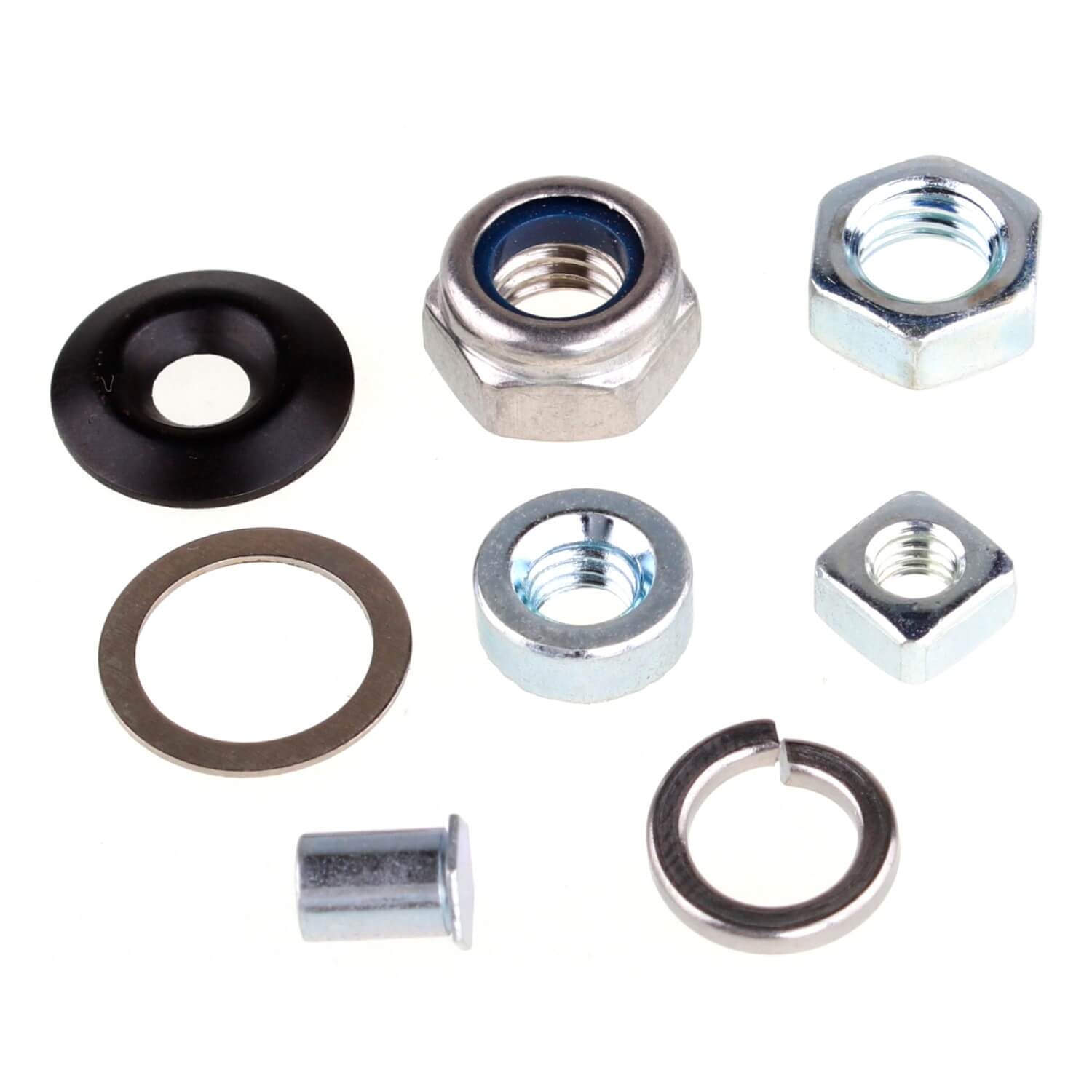

When you’re dealing with fastening setups that use bolts and nuts, washers are really important helper parts. washers play a supporting role: they fill in gaps between parts, spread out clamping force so it’s even, and protect the surfaces of the parts you’re connecting.Common options are stainless steel, carbon steel, and brass.Sometimes people also add surface treatments, like zinc plating or nickel plating, to make them more resistant to rust.That way, they still work reliably even in tough environments.

Application Scenarios of Washers

Picking the right washer makes a big difference for how safe and reliable the whole fastening system is. Here are the main areas where washers are used:

1. Industrial Machinery and Automation

Common types: Flat Washer, Spring Washer

Typical uses: Holding frames of conveyor equipment (flat washers spread out force so the frame doesn’t bend), tightening robotic arm joints (spring washers stop vibration from making things loose), and locking motor bases (carbon steel flat washers match carbon steel bolts and nuts to keep the connection strong).

2. Automotive Transportation

Common types: Stainless Steel Washer, Lock Washer

Typical uses: Connecting fluid pipes on car chassis (stainless steel washers resist corrosion and brake fluid damage), locking drive shafts (lock washers work with slotted nuts to make anti-loosening even better), and installing brake calipers (stainless steel washers keep the connection stable even when it’s damp).

3. Energy, Power, and Heavy Equipment

Common types: Hot-Dip Galvanized Flat Washer, Spring Washer

Typical uses: Putting together generator sets (hot-dip galvanized washers resist rust, so they’re good outside), connecting port machinery (spring washers handle the vibration from the machines running), and holding power towers (hot-dip galvanized flat washers match hot-dip galvanized nuts to make the whole setup more corrosion-resistant).

4. Electronic and Medical Equipment

Common types: Copper Washer, Small Stainless Steel Washer

Typical uses: Grounding server cabinets (copper washers conduct electricity well, so grounding works properly), sealing medical instrument casings (small stainless steel washers don’t scratch the casing surface), and holding small parts inside precision instruments (non-magnetic copper washers don’t mess with the instrument’s accuracy).

How to Customize Exclusive Washers

At Yuhuang, we’ve kept washer customization really straightforward—so you end up with washers that fit your bolts perfectly, no guesswork needed. All you have to do is tell us a few key things:

1.Material: Stuff like 304 stainless steel (it’s awesome at keeping rust away), 8.8-grade carbon steel (super strong for heavy jobs), or brass (works great if you need it to conduct electricity).

2.Type: For instance, flat washers (they spread out pressure nice and even), E-type washers (super easy to slip on and off), or spring washers (stops nuts from wiggling loose when things vibrate).

3.Dimensions: Inner diameter (this has to match your bolt size, obviously), outer diameter (the bigger it is, the more it touches your workpiece), and thickness (just pick this based on how much weight it needs to hold or any gaps it has to fill).

4.Surface treatment: Things like zinc plating (good for damp spots inside) or hot-dip galvanizing (tough enough to handle heavy outdoor use without wearing out).

5.Special needs: Anything a little out of the ordinary—like weird shapes, custom logos on the washers, or ones that can stand up to high heat.

Just shoot us these details, and our team will let you know if it’s doable. We’ll also throw in tips if you need ‘em, and get you washers made exactly how you want‘em.

FAQ

Q: How to choose washer material for different scenarios?

A: Use stainless steel/hot-dip galvanized washers for damp/corrosive areas (e.g., car chassis). Pick copper washers for conduction/sealing needs (e.g., grounding, pipes). For regular industrial use, affordable carbon steel works.

Q: What if washers fail to prevent nut loosening?

A: Swap for lock/spring washers, or pair spring washers with flat washers. Adding anaerobic adhesive on threads also helps.

Q: Should washers be replaced with new bolts/nuts?

A: Yes, it’s recommended. Washers wear out (spring washers lose elasticity, rust forms), so reusing old ones reduces connection stability.

Q: Can spring washers pair with flange nuts?

A: Usually no—flange nuts have a built-in washer-like structure. Extra spring washers may cause over-preload (washer deformation/damage). Only use in extreme vibration (e.g., mining machines) after professional check.

Q: Must rusted washers be replaced?

A: Slight rust (no damage) is usable for non-critical parts (e.g., machine brackets) after cleaning. Replace if rust causes bending, poor fit, or if used in safety-critical areas (e.g., car brakes, medical gear).

Bolts

Bolts Nuts

Nuts Wrenches

Wrenches Spring

Spring