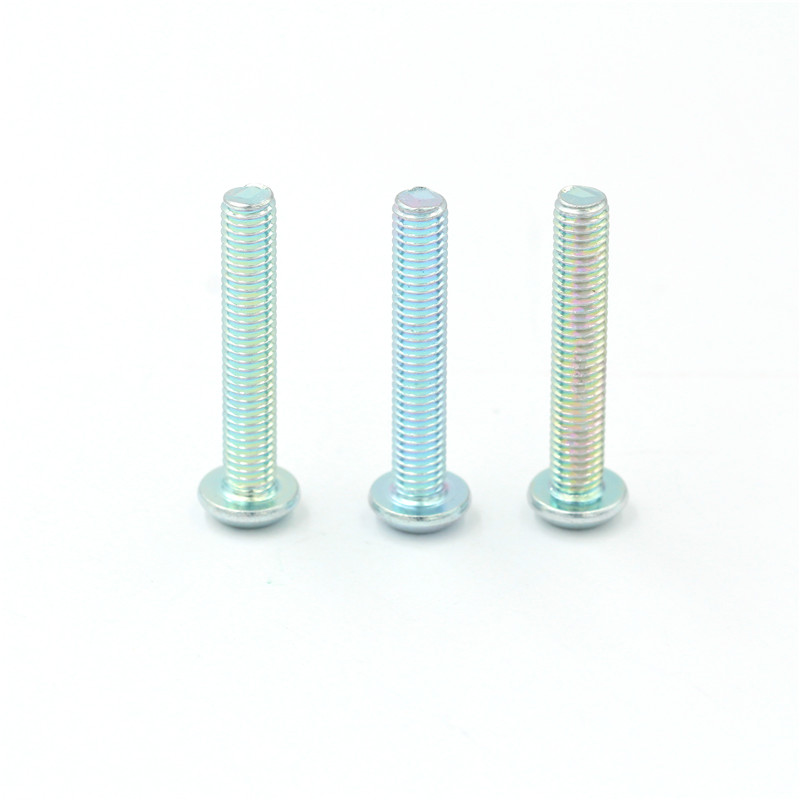

Wholesale SS304 Torx Pin Button Head Security Tox Screw

Description

The stainless steel inner plum blossom anti-theft screw is no stranger. The stainless steel refers to its material, and the plum blossom with column refers to its groove shape, which is like a plum blossom, and there is a small cylindrical protrusion in the middle. Stainless steel anti-theft screw is a kind of screw with good performance, and has many advantages.

The corrosion resistance of stainless steel can be said to be very good in the steel. It can be used for many years to keep bright and clean. It is not easy to rust and has a long service life. And because the plum blossom anti-theft screw with pillar is often used in public facilities that need wind and sunshine, it is a good choice to use stainless steel.

Heat resistance: stainless steel Torx anti-theft screws not only have good heat resistance to high temperature, but also can withstand low temperature, which is very advantageous for use in cold regions.

Good fastening: when using the installation and removal tools, it can be quickly installed and removed, and also has a good fastening effect.

Sealing screw specification

|

Material |

Alloy/Bronze/Iron/ Carbon steel/ Stainless steel/ Etc |

|

specification |

M0.8-M16 or 0#-7/8 (inch) and we also produce according to customer's requirement |

|

Standard |

ISO,DIN,JIS,ANSI/ASME,BS/Custom |

|

Lead time |

10-15 working days as usual,It will based on the detailed order quantity |

|

Certificate |

ISO14001/ISO9001/IATf16949 |

|

O-ring |

We can provide customized services according to your needs |

|

Surface Treatment |

We can provide customized services according to your needs |

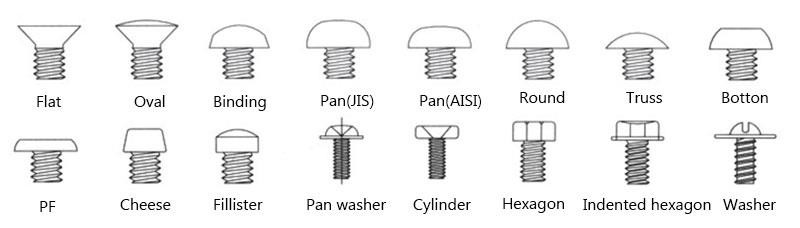

Head type of Security screw

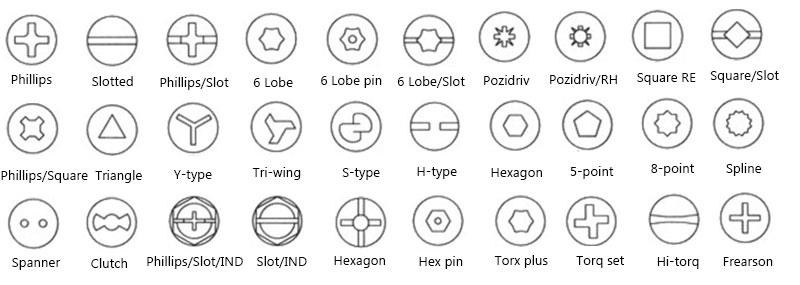

Groove type of Security screw

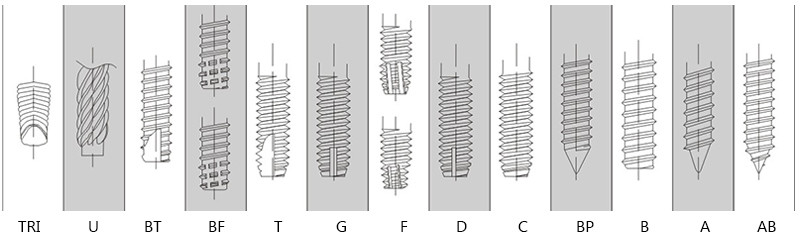

Thread type of Security screw

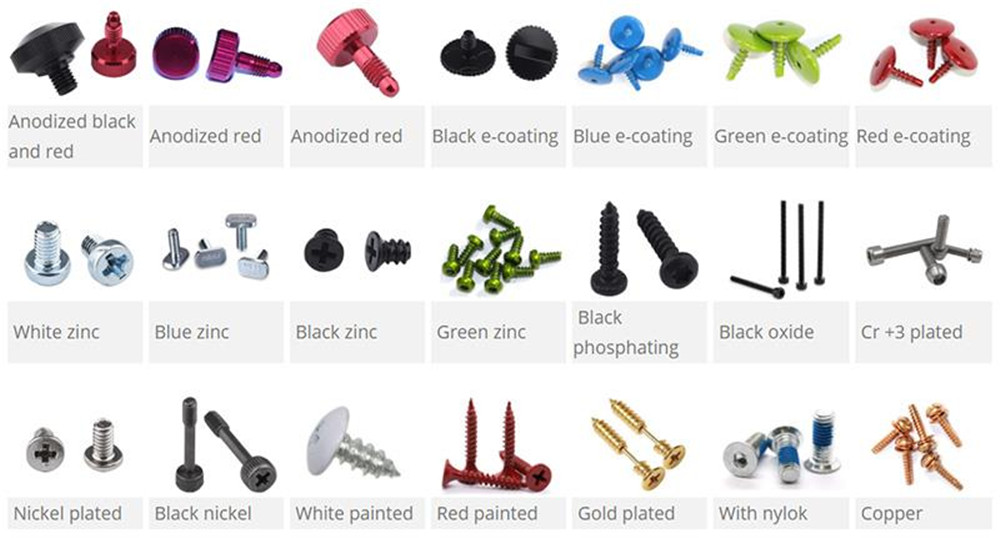

Surface treatment of Security screws

Quality Inspection

We have comprehensive quality management and testing capabilities.

In production, we apply the ERP system for systematic management to ensure the smooth progress of production.

In the inspection, we introduce a combination of worker inspection and machine inspection to conduct a comprehensive quality inspection of the product.

We have the ability to keep the clients’ products, designs, and business information confidential. In the process of cooperation, we will sign a confidentiality agreement with the client.

We use the ERP system for management during the production process to ensure the confidentiality of the production process.

| Process Name | Checking Items | Detection frequency | Inspection Tools/Equipments |

| IQC | Check raw material: Dimension, Ingredient, RoHS | Caliper, Micrometer, XRF spectrometer | |

| Heading | Outward appearance, Dimension | First parts inspection: 5pcs each time

Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours |

Caliper, Micrometer, Projector, Visual |

| Threading | Outward appearance, Dimension, Thread | First parts inspection: 5pcs each time

Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours |

Caliper, Micrometer, Projector, Visual, Ring gauge |

| Heat treatment | Hardness, Torque | 10pcs each time | Hardness Tester |

| Plating | Outward appearance, Dimension, Function | MIL-STD-105E Normal and strict single sampling plan | Caliper, Micrometer, Projector, Ring gauge |

| Full Inspection | Outward appearance, Dimension, Function | Roller machine, CCD, Manual | |

| Packing&Shipment | Packing, Labels, Quantity, Reports | MIL-STD-105E Normal and strict single sampling plan | Caliper, Micrometer, Projector, Visual, Ring gauge |

Our certificate

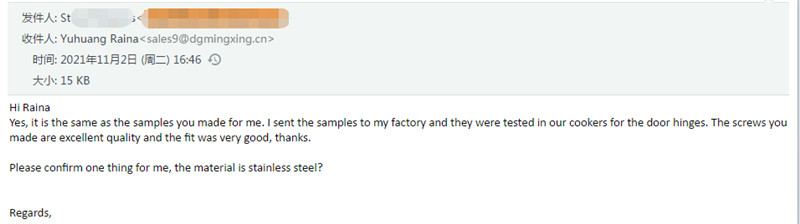

Customer Reviews

Product Application

We can provide you with one-stop Low/High Volume Production, and we have a production workshop with multiple functions. It can meet the various needs of parts production.

In addition to production, we also have other machining services, we can customize rapid prototypes, and get prototype parts in a short time. In addition, we have some additional services, including inspection services, performance, and surface treatment services.